Adhesion: what it is, what is it for, how to improve it

This is the adhesion of materials of different composition and structure, due to their physical and chemical properties. The term adhesion comes from the Latin word adhesion - adhesion. In construction, they give a more narrowly focused and specific designation of what adhesion is - the ability of decorative and finishing coatings (paintwork materials, plaster), sealing or adhesive mixtures to a strong and reliable connection with the outer surface of the base material.

The content of the article [Hide]

- 1 Adhesion, what is it - theoretical foundations

- 2 Adhesion properties of building and finishing materials

- 3 How is adhesion measured?

- 4 Factors that reduce the adhesion of materials

- 5 Methods for increasing adhesion

- 6 Ways to increase adhesion to various materials

- 7 Welding adhesion

- 8 Summing up

- 9 Video: what is adhesion

Adhesion, what is it - theoretical foundations

Adhesion is one of the key material properties in the following areas:

- Metallurgy - anti-corrosion coatings.

- Mechanics - a layer of lubricant on the surface of the elements of machines and mechanisms.

- Medicine - dentistry.

- Construction. In this industry, adhesion is one of the main indicators of the quality of work and the reliability of structures.

At almost all stages of construction, adhesion indicators for the following joints are monitored:

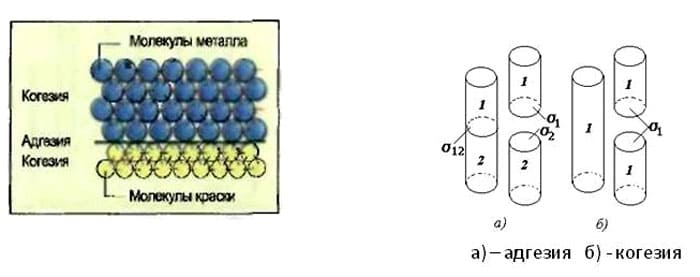

There are three basic principles for adhesive bonding of materials. In construction and technology, they manifest themselves as follows:

- Mechanical - adhesion occurs by adhesion of the applied material to the base.The mechanism of such a connection consists in the penetration of the applied substance into the pores of the outer layer or in connection with a rough surface. An example is painting the surface of concrete or metal.

- Chemical - the connection between materials, including those of different densities, occurs at the atomic level. To form such a bond, the presence of a catalyst is required. An example of this type of adhesion is soldering or welding.

- Physical - on the mating surfaces there is an electromagnetic intermolecular bond. May be caused by static electricity or permanent magnetic or electromagnetic fields. An example of use in technology is painting various surfaces in an electromagnetic field.

Adhesion properties of building and finishing materials

The adhesion of building and finishing materials is carried out mainly according to the principle of mechanical and chemical bonding. A large number of different substances are used in construction, the operational characteristics and specificity of the interaction of which are fundamentally different. We divide them into three main groups and characterize them in more detail.

paints and varnishes

The adhesion of paintwork materials to the surface of the base is carried out according to the mechanical principle. At the same time, the maximum strength indicators are achieved if the working surface of the material is rough or porous. In the first case, the contact area increases significantly, in the second, the paint penetrates into the surface layer of the base. In addition, the adhesive properties of paintwork materials are increased due to various modifying additives:

Construction plasters and dry adhesives

Until recently, construction and finishing work was carried out using various solutions based on gypsum, cement and lime. Often, they were mixed in a certain proportion, which resulted in a limited change in their basic properties. Modern ready-made dry construction mixtures: starting, finishing and multi-finishing plasters and putties, have a much more complex composition. Additives of various origins are widely used:

Such modifiers significantly change the following main characteristics of building mixtures:

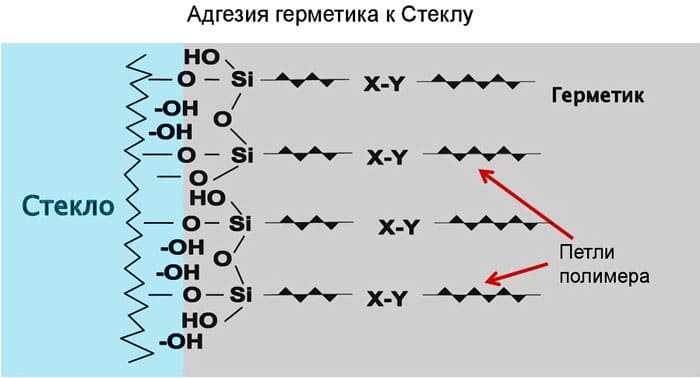

Sealants

Sealants used in construction are classified into three different types, each of which requires specific conditions for high strength adhesion to the substrate material. Let's consider each type in more detail.

Of all the listed varieties, curing sealants provide maximum adhesion to microroughness of the substrate surface. In addition, they are resistant to high temperatures, mechanical and chemical influences. They have the optimal combination of stiffness and toughness, allowing them to maintain their original shape. However, they are the most expensive and difficult to use.

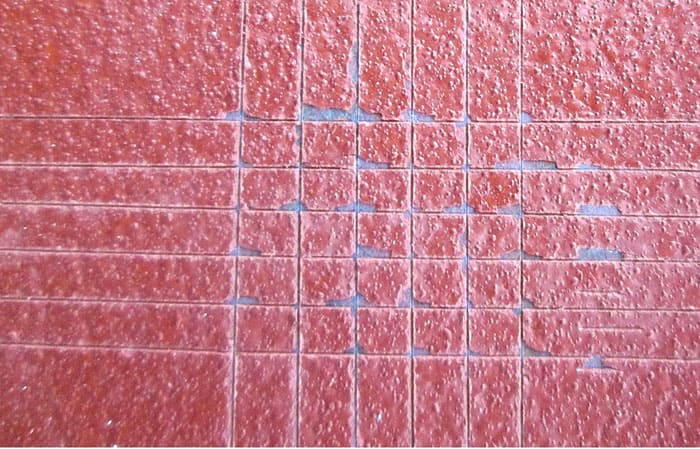

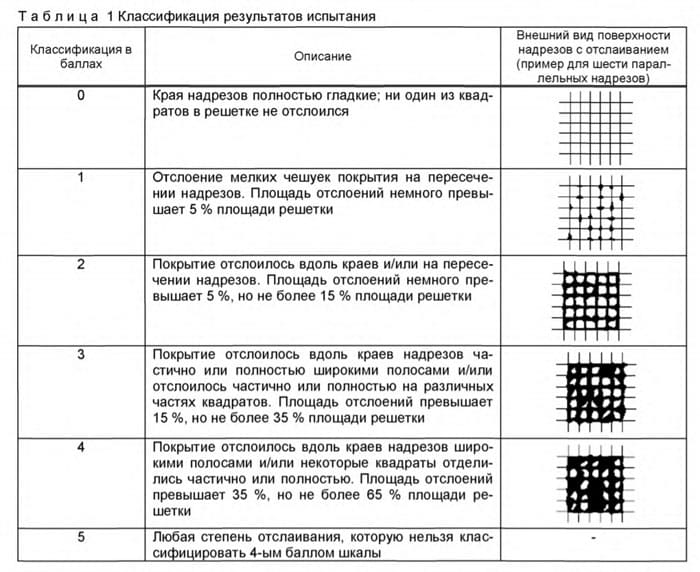

How is adhesion measured?

The technology for measuring adhesion, test methods, as well as all indicators of the strength of the connection of materials are indicated in the following standards:

Whereas previously the adhesion characteristics of materials could only be measured in laboratory conditions, at the moment there are many instruments that can be used directly on the construction site. Most methods for measuring adhesion, both in the field and in the laboratory, involve the destruction of the outer covering layer. But there are several devices based on ultrasound.

Factors that reduce the adhesion of materials

Various physical and chemical factors influence the decrease in adhesion. The physical temperature and humidity refers to the environment at the time of application of decorative, finishing or protective materials.Various contaminants, in particular, dust covering the surface of the base, also reduce the adhesive interactions. During operation, ultraviolet radiation can affect the strength of the connection of paints and varnishes.

Chemical factors that reduce adhesion are represented by various materials contaminating the surface: gasoline and oils, fats, acidic and alkaline solutions, etc.

Also, the adhesion of finishing materials can be reduced by various processes that occur in building structures:

Methods for increasing adhesion

In construction, there are several universal ways to increase the adhesion of decorative finishing materials to the base surface:

- Mechanical - the surface of the base is roughened to increase the contact area. To do this, it is treated with various abrasive materials, notches are applied, etc.

- Chemical - various substances are added to the composition of the applied protective and finishing materials. These are, as a rule, polymers that form stronger bonds and give the material additional elasticity.

- Physicochemical - the surface of the base is treated with a primer that changes the basic chemical parameters of the material and affects certain physical properties. For example, a decrease in moisture absorption in porous materials, anchoring of a loose outer layer, etc.

Ways to increase adhesion to various materials

Let's take a closer look at the methods of increasing adhesion for various materials used in construction.

Concrete

Concrete building materials and structures are widely used in construction. Due to the high density and smoothness of the surface, their potential adhesive properties are quite low. To increase the strength of the connection of finishing compounds, the following parameters must be taken into account:

Metal

The method and quality of surface preparation play a key role in the strength of the connection of paints and varnishes with a metal surface. At home, it is recommended to do the following:

Wood and wood composites

Wood is a porous surface with a lot of unevenness and does not experience any particular problems with the strength of the connection of finishing materials. But there is no limit to perfection, therefore, various technologies have been developed to improve adhesion in combination with maintaining the protective and decorative properties of the finish itself. Their use, for example, in combination with acrylic paints, significantly improves weather resistance, resistance to ultraviolet fading, and gives biological protection to the material. The surface of the wood is treated with a wide variety of primers, most often based on boron compounds and nitrocellulose.

Welding adhesion

Welding is one of the most durable methods of joining metal structures. This is the adhesion of the molecules of the two elements without the use of intermediate or auxiliary substances - glue or solder. This process takes place under the influence of thermal activation. The outer layer of the elements to be joined is heated above the melting point, after which intermolecular convergence and joining of materials occurs.

Electric welding seam. The connection of two parts by electric welding is adhesion, since the metal used in the electrode acts as an adhesive

The following factors can be an obstacle to high-quality adhesion during welding:

Gas or plasma welding of metal is cohesion, since the molecules of the two elements are connected as a result of the material melting

Summing up

Adhesion is one of the most important characteristics of many processes in modern construction, so new methods are being developed to increase it. Their use will provide greater durability to building structures and finishing materials, which ultimately will provide significant savings.

Video: what is adhesion