Crown for concrete - how to choose and an overview of prices for popular models

Among the variety of construction tools that are in personal use by ordinary users, not many have in their arsenal bits designed for drilling concrete, which is due to their narrow profile use. A concrete crown - what it is, advantages and disadvantages, types and options for selection, as well as an overview of prices for popular models and user reviews - this is the topic of this article in the online magazine homemaster.techinfus.com/en/.

The content of the article [Hide]

- 1 What is a concrete crown and why is it needed

- 2 Device and principle of operation

- 3 Types of concrete crowns, their advantages and disadvantages

- 4 Selection of products by parameters

- 5 Recommendations for the use of popular concrete crown sizes

- 6 Leading manufacturers of concrete crowns

- 7 Review of prices for drill bits for concrete drills, depending on the type and size

- 8 Video: holes for the socket with a Keos diamond core bit

What is a concrete crown and why is it needed

Currently, concrete is used at all stages of construction and installation work: from the construction of the foundation and enclosing structures to pouring ceilings and screeds for various purposes. In this regard, the presence of a drilling tool capable of drilling holes in concrete is very important for any type of construction (housing, utilities, industrial, etc.). A bit for concrete is a type of drilling tool, with which holes are drilled in building structures made of concrete. This operation is necessary when performing such work as:

Model with an adapter series "DIAM SDS +" (68x8xM16) for mounting wiring accessories and socket outlets

Device and principle of operation

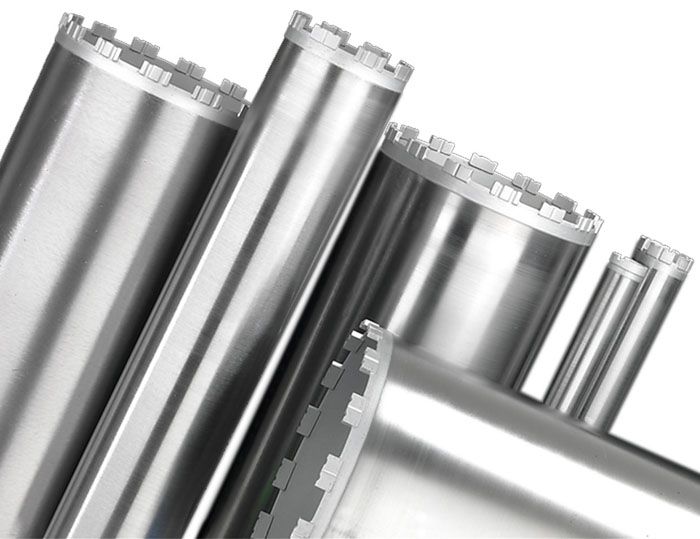

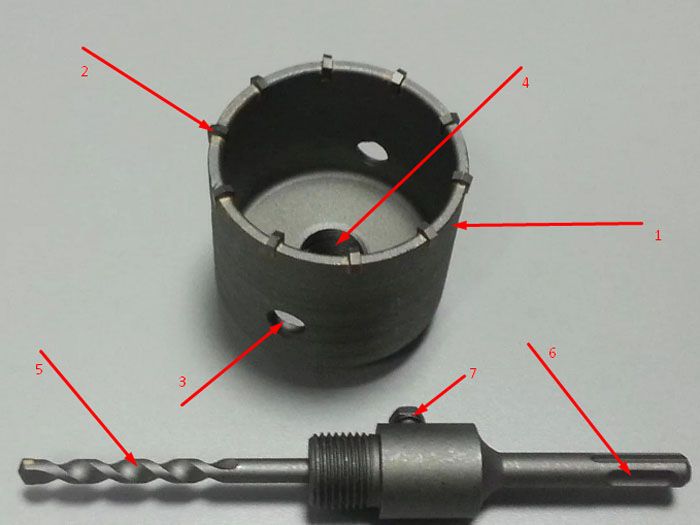

Structurally, a concrete crown is a pipe of a certain diameter, on the surface of which there are holes designed to remove dust and concrete fragments formed during the work. One side of the pipe is plugged, and there is also a hole for installing a flange with a centering drill and a shank.

The shank has special grooves for fixing the bit in the used drilling tool (hammer drill, drilling rig, hammer drill), and the drill ensures the exact location of the tool when drilling. On the second side of the pipe, on its surface, there are mounted cutting elements (teeth, special coating, etc.), which provide drilling. The size of the resulting hole corresponds to the outer diameter of the pipe.

The main structural elements of the crown for concrete: 1 - body (pipe); 2 - cutting elements (teeth); 3 - holes for removing dust and concrete fragments; 4 - hole for flange installation; 5 - centering drill; 6 - shank with grooves for fastening; 7 - bolt for fixing the centering drill.

In models with a collapsible design, there is a bolt on the flange surface that provides fixation or replacement, if necessary, of the centering drill.

The principle of operation of the tool is based on driving the crown into rotary motion by means of an electric motor and at the same time bringing it into contact with a concrete surface. The cutting elements sink into the concrete, crushing it, and the centering drill ensures precise positioning at the drilling site.

Depending on the type of hand-held tool used, drilling can be of impact and non-impact type, which is determined based on the strength of the concrete being processed.

Types of concrete crowns, their advantages and disadvantages

According to the material used in the manufacture of cutting edges, concrete crowns are of three types:

From carbide metals

Bits of this type are used for hammer drilling. In their design, the cutting element is teeth made of hard alloy metals, which are soldered along the surface of the working edge. The diameter of this type of crown is 20-100 mm, and the shank is made in accordance with the SDS-Plus and SDS-max standards.

The advantages of products of this type include low cost and a variety of standard sizes, and the disadvantage is the possibility of destruction of the cutting tooth in contact with reinforcement embedded in concrete.

Tungsten carbide alloy

This type of tool is designed for hammerless drilling. The working surface of the bit is coated with tungsten carbide, which ensures the process of drilling in concrete. The standard sizes of such products can be different, they can be sold as piece goods or sold in sets.

The advantages of this type of crowns are the possibility of using facing tiles for drilling, which expands the functionality of the tool, and the disadvantage is instant destruction when it comes into contact with metal (reinforcement, profile, rolled metal, etc.).

Diamond grit

Diamond core bits are used for drilling with and without moisture, in shock-free operation.The cutting surface of this type of product consists of segments cut on the edge of a diamond-coated bit.

The industry produces crowns of this type in a wide range of standard sizes, which is due to their demand when performing work for various purposes. The advantages of diamond core bits are:

The main disadvantage of this type of product is its high cost.

Selection of products by parameters

When choosing a crown for concrete, it is necessary to take into account such parameters as:

If everything is clear with the diameter and length of the product, because these parameters are set by the geometric dimensions of the hole, then it is necessary to dwell on other characteristics separately. The industry produces crowns with three types of attachment:

As for the type of drilling, as it was already written above, diamond bits are best used with a wet method of drilling, and carbide and tungsten carbide bits - with a dry one.

Recommendations for the use of popular concrete crown sizes

Different standard sizes are in demand to varying degrees, which is associated with the purpose of the holes being made, which determine this indicator of tool use.

Diamond core bit Ø 68 mm for concrete

The demand for this standard size is due to the fact that when installing wiring accessories (when laying hidden wiring), special mounting boxes (socket boxes) are used, the diameter of which is 65-68 mm.

Drilling holes for the installation of junction boxes and installation products is an important operation when installing hidden electrical wiring.

To perform such work, both carbide and diamond bits are used, but since diamond ones have a longer service life, then they are used by professionals. When performing electrical work using crowns of this size, you must:

The drilling method (dry or wet) is selected in accordance with the type of bit and wall structure, as well as with the technical capabilities at the construction site

Bit for concrete for rotary hammer Ø 110/120 mm

Diameter 120 mm for this type of tool is the largest among those used for domestic purposes. For industrial production, SDS-max diamond core bits with a shank are also available in larger sizes (up to 600 mm), but due to their low demand in retail, they cannot be found. When performing work using diamond tools, it must be remembered that:

In addition, when working with crowns of different types, it is necessary:

Leading manufacturers of concrete crowns

On the domestic market of construction tools, there are concrete crowns of domestic manufacturers and foreign companies. Among the most popular are products of such companies as:

Confirmation of the popularity of the concrete crowns of the above listed brands are the reviews of real users left by them on the Internet. Here is some of them.

Review of prices for drill bits for concrete drills, depending on the type and size

Crowns for concrete are sold in shops and retail chains specializing in the sale of tools for various purposes and building materials. Their cost depends on the type of product, its size and the manufacturer's brand.

There is a department for the sale of consumables in every store and retail network that works with hand tools and building goods

The following table shows the price of various types of concrete drill bits as of Q3 2018 when sold through the retail network.

| Crown type | Brand name | Cost (as of August 2018), rubles with an outer diameter, mm | ||||

|---|---|---|---|---|---|---|

| 30 | 55 | 68 | 80 | 120 | ||

| Diamond | "Keos" | - | - | 2400 | 2900 | 4500 |

| "Bosch" | 1800 | 2700 | 3500 | 3900 | - | |

| "Anchor" | 1100 | 1400 | 1800 | 2200 | 2500 | |

| Carbide | "Keos" | - | - | 860 | 980 | 1550 |

| "Hagwert" | 580 | 650 | 860 | 1200 | 1400 | |

| "Anchor" | 375 | 500 | 550 | 650 | 800 | |

| Tungsten carbide | "Anchor" | 120 | 180 | 250 | 290 | - |

| "Zubr" | 130 | 185 | 210 | 280 | 420 | |

Video: holes for the socket with a Keos diamond core bit

Due to the fact that in domestic conditions, concrete crowns are most often used when installing electrical wiring, our editorial staff offers for viewing a video about using a Keos brand crown with a diameter of 68 mm to install an electrical outlet box.