SIP panels: what is it, features of the material, advantages and useful properties

Buildings made of alternatives to concrete and brick materials. Technologies like these hold great promise. When choosing modern materials, many people have a question: what are SIP panels? This material is already well known and has proven itself very well. Before purchasing this material, you should familiarize yourself with its pros and cons, as well as with the main characteristics.

Different types of houses are made of similar slabs, most often they are cottages with one or two floors.

The content of the article [Hide]

SIP panels: what is it and what are they used for?

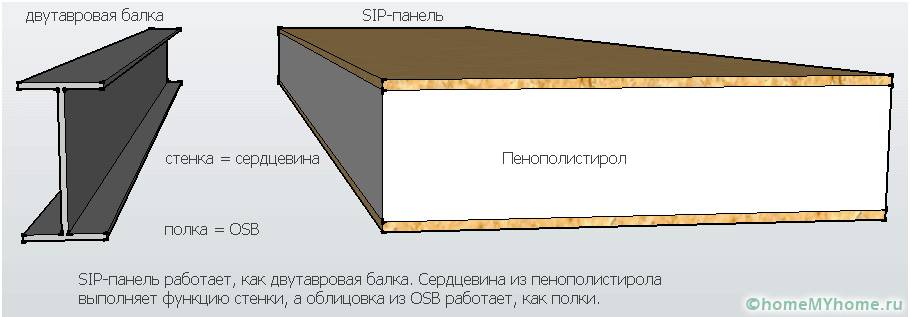

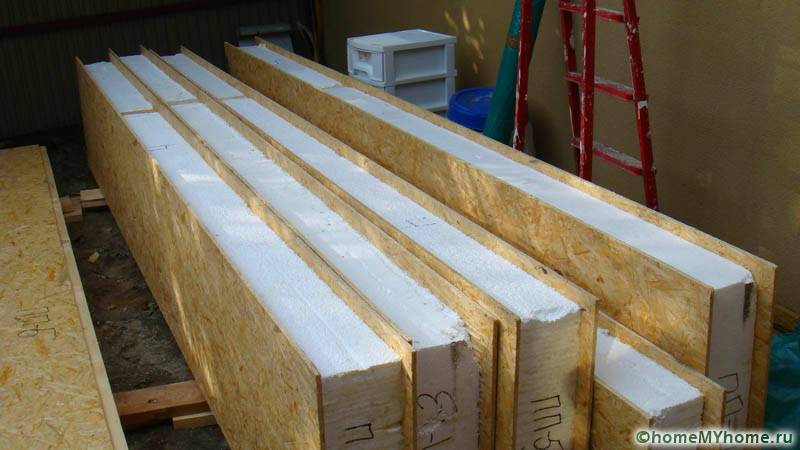

SIP panels, photos of which can be seen in our review, are durable and convenient building materials. It consists of two OSB boards, which are separated by a layer of insulation - expanded polystyrene. All interlayers are attached with polyurethane glue. OSB consists of wood chips, which are compressed using special resins. Such products are easy to install and efficient.

Buildings made using this technology are called "Canadian". The end part of the sip panel is equipped with grooves with which the elements are attached to each other.

SIP panels: reviews of residents, pros and cons

They can say about the positive sides of the sip panels, reviews of residents, the pros and cons of the material will allow you to make the right choice.

This construction canvas has the following advantages:

To get a better idea of what sip panels are, it is worth reading the reviews that point out some of the shortcomings of the material:

The construction of buildings from this material requires the construction of lightweight foundation options

Basic material properties

To understand what a SIP panel is, you need to study the important characteristics of this material. An important parameter is the value of the heat transfer of the product. The resistance index of the plates is 2.8 W / mC, with a foam polystyrene thickness of 100 mm. This value corresponds to the norms of SNiP. If the thickness is more than 220 mm, then this value will reach 5. For comparison, a layer of brick of 400 mm with an additional layer of mineral wool of 80 mm reaches 2 W / m ° C.

Features of houses from SIP panels: photos and options

Houses made of SIP panels have special properties. Photos allow you to see the best options. Details for the frame are made in specialized industries. All elements of the future building are prepared at the factory and then transported to the construction site.

A building of any configuration can be erected from SIP-plates. At the same time, great opportunities are provided when choosing a design.

These houses have the following positive aspects:

You can use such a structure even in severe frosts, if you properly insulate the house and conduct a high-quality heating system

Related article:

Average cost of SIP panels

What are SIP panels? Reviews will help you find out better. In this case, you should pay attention to the cost of production.

The table shows the prices taking into account the type of filler.

| Panel (filler) type | Thickness, mm | Average price per m2, rub. |

|---|---|---|

| Expanded polystyrene | 50/80/100/150/200 | 870/920/940/1020/1100 |

| Polyurethane foam | 50/75/100/150 | 1140/1340/1600/2080 |

| Basalt fiber | 50/75/100/150 | 1040/1180/1350/1660 |

The price may vary depending on the overall dimensions of the canvas.

| Dimensions, mm | Average cost, rub. |

|---|---|

| 2500*1250*118 | 2780 |

| 2500*1250*168 | 3200 |

| 2500*625*174 | 2050 |

| 3030*1220*170 | 2990 |

There are certain criteria for evaluating the additional thermal insulation material that is used in the sip structure

Varieties of insulation

For building a house, SIP panels are considered an excellent solution. What is it, the used heaters.

The following options are used as heat insulating and sealing materials:

Related article:

How to choose material: useful recommendations

It is recommended to select only high quality SIP panels. In this case, you should not focus only on considerations of economy. Excessive savings can lead to the need for an early repair or dismantling of poor quality canvases. In cheap material, poor quality glue is often used, which is unevenly distributed. In this case, the layers of OSB can be easily separated even with slight pressure.

In such products, poor polystyrene can be used, which easily ignites and releases toxic substances.

Quality products must be highly resistant to combustion and even self-extinguishing.

The following recommendations will help to verify the quality of SIP panels:

The method of erecting buildings from ready-made vulture panels is unique in the speed of work. Moreover, even a two-story cottage can be created in 12-15 days. By choosing the right material, as well as observing the construction technology, you can build comfortable and economical housing from modern slabs, in which you can live throughout the year.

Video: the price of building a house from SIP panels