From manufacturing to installation: DIY paving slabs

Every year, concrete pavement pavement “conquers” new territories not only on city roads, but also in private estates. Therefore, home-grown owners, trying to cut costs, are looking for ways to independently lay paving stones. And for some, do-it-yourself paving slabs are the main article of budget savings. In today's review, we will tell you how to properly make paving slabswhat production methods exist, what tools, equipment you need for this. Along the way, you will learn about the manufacture of paving molds and find detailed step-by-step instructions for self-installation.

The content of the article [Hide]

- 1 Which tile is better and more profitable - homemade or industrial

- 2 Paving Slab Production Methods

- 3 Making paving slabs with your own hands at home: step by step instructions

- 3.1 Equipment and tools for the production of paving slabs

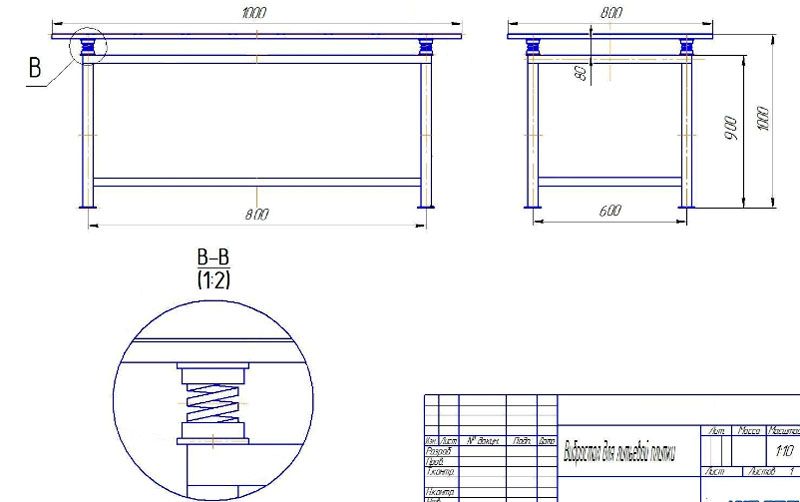

- 3.2 DIY vibrating table making drawings

- 3.3 DIY molds for paving stones and paving slabs

- 3.4 Paving slab mortar composition - components

- 3.5 Working cycle for the production of paving slabs

- 3.6 Drying rules for paving slabs and paving stones

- 3.7 Features of demoulding finished products

- 4 How to check the quality of the finished tile

- 5 Laying paving slabs with your own hands - a short step-by-step instruction

Which tile is better and more profitable - homemade or industrial

Having set out to lay out the track on the site with concrete tiles, the questions of the benefits and quality of such products always arise: which is better and more economical - to do it yourself or buy? Let's consider this question point by point:

Are you ready for such risks? What if the investment in raw materials and manufacturing of the necessary equipment does not pay off? Where are you going to add low-quality paving slabs? These are the questions to ask everyone who wants to start producing paving slabs for their own needs. In most cases, it is more profitable to buy paving slabs and start laying it yourself. If this is not about you, read on and learn the secrets of concrete science.

Paving Slab Production Methods

There are several ways to make concrete paving. The characteristics and durability of products depend on the type of production.

Vibrocompression

A similar method of making tiles consists in hard compaction - pressing a semi-dry concrete mortar... At the same time, the minimum amount of water required for its mixing and hardening is added to the cement-sand composition. And, as you know, the less water in concrete, the better it is.

Products with a thickness of more than 35 mm are made in a similar way. It is these products that are called paving stones. Of the advantages, it can be noted:

It is for these reasons that city utilities opt for just such a sidewalk covering, turning a blind eye to the monotony of forms and the dullness of the color palette. The disadvantages also include the impossibility of making equipment from improvised means for the production of paving stones with your own hands and its considerable cost. So, if you have "laid eyes" on such products, you will have to buy them.

Vibration casting

Vibro-casting tiles are distinguished by their small thickness - from 10 to 35 mm, as well as by the variety of shapes with ornate patterns and unusual patterns. But, in comparison with the previous type, it has low strength and frost resistance. The process of making such products is a little more complicated and consists of the following stages:

This method is also used for the production of concrete facing stones for facades, fences, flowerpots, parebriks, overhead steps, balusters and borders.

Although there are many steps in one production run, it is not so difficult to reproduce them with everything you need. Therefore, we will consider home-made tiles using this technology. A small note, if you are planning to make ceramic tiles with your own hands, then you can forget about it, since the technology itself is so complex that some manufacturers cannot. And the raw material base for it is not as easy to get as for concrete products.

Related article:

Making paving slabs with your own hands at home: step by step instructions

Where does any production begin - of course, with the competent arrangement of equipment and planning of the workflow. Let's consider everything in detail.

Equipment and tools for the production of paving slabs

What is required to start a "home" tile production:

Don't forget about inventory:

In principle, this is all that is required for the first batch. You will figure out what will be more convenient for you "along the way".

DIY vibrating table making drawings

As already found out, a vibrating table is needed for self-made tiles. Although it is not a tricky design, the assembly still requires special attention and care. The video below will tell you in detail how to do it better:

Also, our small selection of drawings will help technicians understand the structure of the sealing structure.

DIY molds for paving stones and paving slabs

Now the most exciting thing is the forms for the manufacture of paving stones, or rather, paving slabs. Today it is possible to purchase practically any standard size with any ornament. But you need to take into account the ratio of the shape perimeter and the thickness of the future product. The most successful sizes are considered to be 300 × 300 cm or less.

If buying forms for paving slabs is not your option, we offer a small video tutorial that will tell you how you can make them yourself, literally from improvised means:

Paving slab mortar composition - components

The selection of the optimal concrete composition of the working mixture for sidewalk products is not an easy task. But if someone succeeded, then why can't we? What you need to know about materials:

The selection of the composition of this type of concrete is standardized by GOST 7473-94. But this does not mean that the main dosages are prescribed there. This technical document describes the general rules and regulations that M300 concrete must comply with. We also provide a rough selection of the squad. For each production, equipment and raw material, they are adjusted:

Working cycle for the production of paving slabs

So how is paving slabs made with your own hands? Let's take a closer look.

Drying rules for paving slabs and paving stones

A good thermal and humidity regime is a guarantee of the quality of the future product. Of course, concrete can "reach" in natural conditions, but during this long period, which can take up to several days, concrete can erupt into the mold so much that when the formwork is removed, the front surface will be defective. Therefore, we provide room heating up to about + 40 ° C and cover the products with foil. After about a day, you can pull out the finished tiles, but only carefully.

| Photo | Stage | Description |

|---|---|---|

| After steaming | Products after aging |

Features of demoulding finished products

The stripping is carried out according to the following principle:

We leave the finished products to stand for about a week, and send the forms to the sink.

How to check the quality of the finished tile

So, the tile came out of shape without damage, but you still have doubts about how high-grade it turned out? There are several ways to check this, by the way, you can also apply them for purchased tiles (such methods do not apply to paving stones, only to vibrocasting products):

Laying paving slabs with your own hands - a short step-by-step instruction

Laying technology paving slabs do it yourself is not difficult, although it requires accuracy and prudence. You also need to understand that laying paving slabs on sand thickness up to 3.5 cm is not performed, only for concrete mortar. Therefore, we will consider just such a technology:

Above is a brief instruction, but the video will tell you more about laying paving slabs.

Related article:

Video: DIY paving slabs

As you can see, there is nothing unrealizable in the independent production of paving slabs. You just need to carefully prepare and follow a rigorously verified technology. And then only high-quality products will turn out.