Do-it-yourself bed made of wood - general recommendations and step-by-step instructions for making

The furniture market in our country is quite saturated with models of domestic and foreign production, in the manufacture of which various materials and components are used. Nevertheless, there are situations when, for whatever reason, there is a desire or need to make something with your own hands from improvised or initially required materials. Do-it-yourself wood bed - step-by-step instructions for making a single, one-and-a-half and double models, as well as a bed-house and using a lifting mechanism - this is the topic of this article in the online magazine homemaster.techinfus.com/en/.

Wood is an environmentally friendly material, so it is in demand in the manufacture of furniture for various purposes

The content of the article [Hide]

How to do it yourself - general recommendations

When making your own furniture, a very important point is the correct selection of wood species, because not all of them are equally good both in work and in future use. All tree species are divided into three categories:

In addition, different breeds differ in cost and availability, therefore, when making furniture yourself, you should also pay attention at this point. Before starting work, it is necessary to prepare the required tools and devices, material and necessary accessories, as well as mechanisms, if any, are required. The next stage will be the development of a sketch or drawing of the manufactured product with the study of the connection nodes of individual elements, as well as options for decorating wooden surfaces.

The design and size of a wooden bed can be completely different and are determined based on the user's needs and his ability to work with hand tools and woodworking equipment

DIY wooden bed - step by step instructions

All work on self-production of a wooden bed can be divided into several stages: preparatory, manufacturing and assembly, decoration and finishing.

Preparatory stage

During this period, the dimensions of the manufactured piece of furniture are determined, and since a mattress is placed on any bed, its perimeter must correspond to its dimensions.

Based on the requirements of GOST and the size of the mattresses produced, the dimensions of the bed produced must correspond to the following values, namely:

| Bed type | Length, cm | Width, cm |

|---|---|---|

| One bedroom | 190-210 | 70-90 |

| One and a half | 200 | 130 |

| Double | 200-210 | 160-180 |

Having decided on the dimensions, you should think over the design of the bed and the style of its design, draw up a drawing or sketch, which reflects all the main dimensions, as well as the attachment points and connections of individual structural elements. Based on the manufactured drawing, a list of materials required for work is compiled, it can be:

To complete the work, you will need the following tool:

Manufacturing and assembly

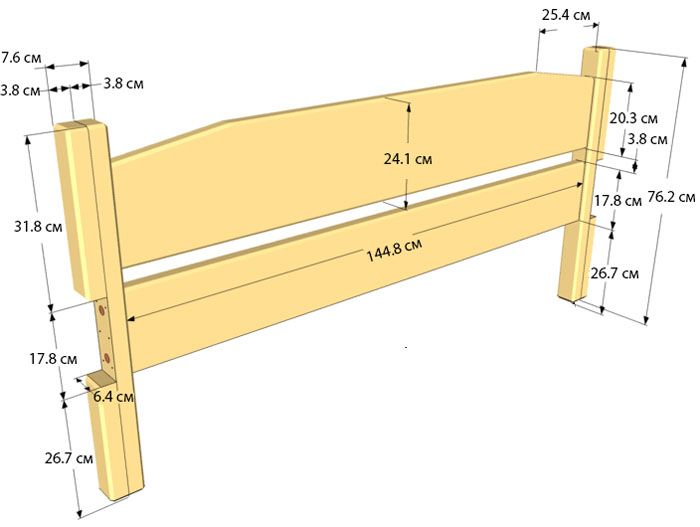

The manufacturing process for beds of various sizes is exactly the same, so let's consider one of them - a double bed with dimensions of 2000 × 1600 mm made of natural lumber.

Decorating and finishing

When the bed is assembled, all wooden surfaces should be sanded or sanded and then covered with wood stain and varnish.To apply varnish and stain, special cotton swabs and paint brushes, or a spray gun and air compressor can be used. The choice of color and type of material used for decoration is determined by each user purely individually, based on personal preferences and design style. bedroom.

Related article:

Making a special wooden bed

Sometimes there are cases when it is necessary to have a bed of a non-standard shape or design, these include the following: bunk and a bed-house, with a lifting mechanism and other technical devices.

How to make a bunk bed with your own hands at home

The steps for making a bunk bed are exactly the same as in the case of a conventional design, the only difference is that the two berths are located one above the other.

As a rule, a bed of this design is intended for children, therefore, during its manufacture and installation, special attention should be paid to such points as:

Making a house bed with your own hands

A house bed is also an option for arranging a sleeping place for a child, which can be one- or two-tier, depending on the number of children in the family, as well as the idea of \ u200b \ u200bdesigning such an element of furniture.

There can be a huge number of design options for a bed of this type, and only the financial component of this process and the design abilities of the designer of the structure can become limitations. Depending on the gender of the child and his interests, the bed-house can include sports equipment and playgrounds, a work or school corner. Due to the significant overall dimensions, it is difficult to place beds of this type in a room of standard sizes, therefore, as a rule, owners of suburban real estate and large apartments turn to such furniture.

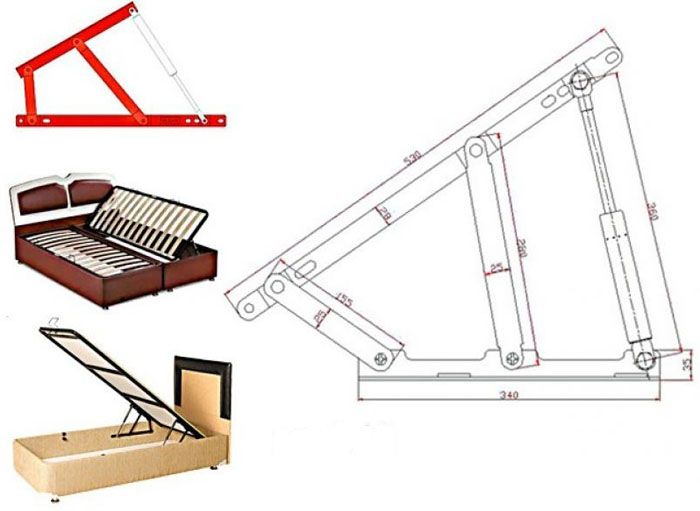

Features of making a bed with a lifting mechanism with your own hands

For owners of small apartments and studio apartments the issue of effective use of the usable area is very important. One of the options for rational use in this case is the purchase and operation of a bed with a lifting mechanism.

A bed with a lifting mechanism can be made independently, while you should be aware of some of the nuances of the work, which can be formulated as follows:

When making with his own hands, the master performing the work himself chooses the type of lifting mechanism, as well as the materials used for the supporting elements of the structure, and its decoration.

Related article:

Video: making a double bed

A bed of wood can be made by both a novice master and an experienced furniture maker who has special woodworking equipment. In the second case, the bed can be decorated with various types of decor, which will greatly decorate the bedroom where it will be installed. The following video will tell you how to make a beautiful double bed.