Chipboard material - what is it and what is it "eaten" with?

It is difficult to imagine a house, apartment, office, study, etc. without furniture. And if earlier it was made exclusively from natural wood, creating beautiful things, and sometimes even real masterpieces, then when the production of tables, cabinets, beds and much more were put on stream, we had to look for materials that would make it possible to reduce the cost of the manufacturing process and the products themselves. At first, these were the so-called furniture boards, thick plywood, and then such materials as chipboard, chipboard, MDF, etc. came to replace them. A simple layman, far from construction and furniture business, will ask a natural question: what is it - chipboard, chipboard and MDF? In this article we will try to answer it and decipher these abbreviations, find out the advantages and disadvantages of the best manufacturers, as well as what kind of furniture can be made from one material or another.

The content of the article [Hide]

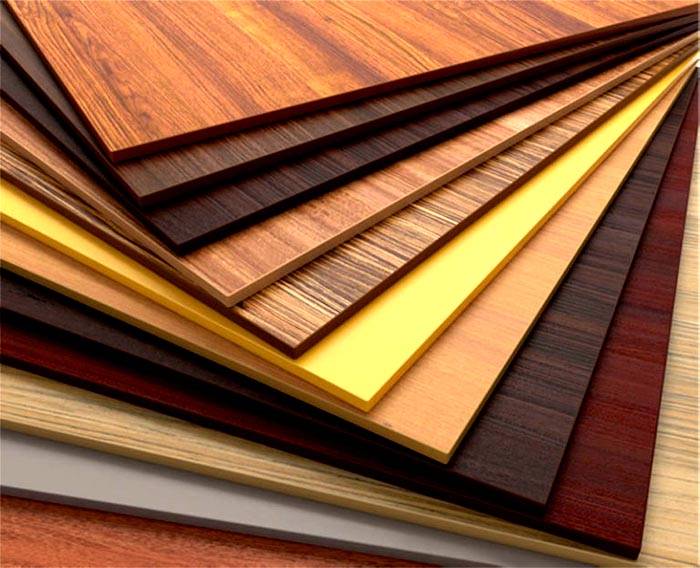

Decoding what it is chipboard: differences from other materials and production technology

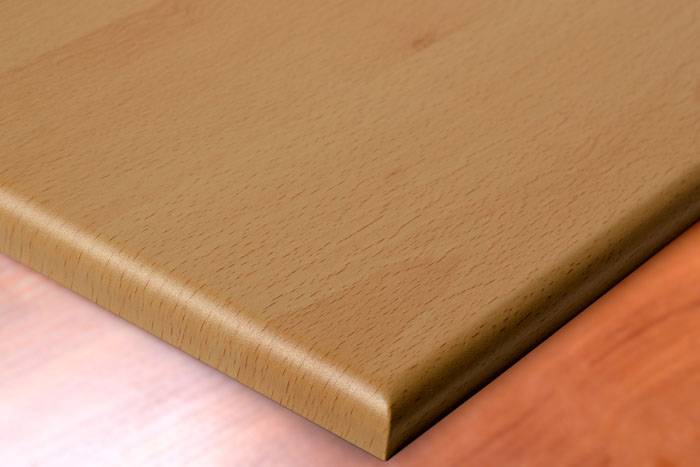

In principle, most people know that chipboard is particle board, which is made by pressing natural wood sawdust using a special adhesive (various formaldehyde resins). And to the question - what kind of chipboard material is it, or as it is also called “laminate”, We will answer - the same chipboard, only covered with a special decorative film applied under high pressure.

But a second logical question may arise: what is the difference between chipboard and chipboard? Is it really just the presence of a decorative layer? By and large - yes! However, this difference predetermined the field of application of these materials. Particleboard is used in construction, furniture production, etc., but only in cases where a beautiful appearance is not required or as a base. Due to its decorative coating, chipboard is used in the production of furniture, as well as in the construction industry as a facing material.

For the production of furniture, which is better - laminated chipboard or MDF

Before deciding which material is better for making furniture, you first need to find out their characteristics, weaknesses and strengths, listen to the opinion of experts and only after that draw any conclusions. And, if we have already found out that the production technology of laminated chipboard consists in pressing wood chips using an adhesive and applying, subsequently, a decorative layer. Now let's look at how MDF is made or, more correctly, MDF.

The abbreviation MDF, in the Russian version, should be understood as a finely dispersed fraction of wood chips. But the true, English name gives a slightly different concept:

That is, MDF is essentially nothing more than a medium density fiberboard.

In the production of MDF, sawdust and shavings are used, crushed to the state of individual fibers, which makes it possible to take almost any waste from woodworking enterprises as raw materials. The main component is crushed to the size of a crumb, after which it is cleaned with hot steam and ground to the smallest particles. At the last stage, the prepared raw material is mixed with special resins and hot pressed. The output is a material that is not inferior to natural wood in some characteristics. To understand what is better for furniture - MDF or chipboard, you need to compare their main characteristics.

Density and strength

These parameters directly depend on the raw materials used. Since laminated chipboard is made from solid shavings arranged in random order, the average density will be in a fairly wide range - 350-650 kg / m3... In the manufacture of MDF, the main component is crushed almost to a homogeneous mass, therefore, the differences in average density are insignificant - 720-870 kg / m3.

Sustainability

Now it is worth considering how chipboard differs from MDF in terms of environmental safety. Here, particle board is clearly inferior to MDF, since formaldehyde resins are used as an adhesive, which actively evaporate and are harmful to the human body. For environmental safety in Europe, chipboard is divided into two classes - E1 and E2. Domestic manufacturers are guided by GOST, which does not allow classification. Boards of class E2 cannot be used for the manufacture of furniture intended for residential premises (especially for children), and in some countries they are generally banned and discontinued.

The technology of MDF production involves dry pressing of the main component under high pressure and high temperature using urea resins as a binder, which are not so harmful to humans.

Moisture resistance

By itself, the particle board does not resist moisture well - when wet, it actively absorbs water, swells and increases in volume up to 30%. Chipboard is more resistant to moisture, thanks to the laminated coating and, in some cases, is even used as countertops in budget models.However, if the outer coating is damaged, moisture acts on the material, just like on ordinary chipboard.

Since MDF boards themselves are quite dense material, even without a decorative layer, the material will resist moisture well. Even when it gets into water, MDF can retain its original shape for several hours, which surpasses even some types of natural wood.

Moisture resistance is an important parameter that must be taken into account when determining which is best for the kitchen: chipboard or MDF. Knowing the main characteristics, it becomes much easier to choose the material for the manufacture of a kitchen, bed, cabinet, etc. In addition, there is the possibility of combining boards, for example, a frame can be made from a simple or laminated chipboard, and MDF can be used for decoration and production of facades.

Each type has its own advantages and disadvantages. The comparative table will better show the differences between laminated chipboard and MDF:

| Material | Dignity | disadvantages |

|---|---|---|

| Chipboard | strength rigidity practicality low cost rich selection of colors and textures ease of processing possibility of staining | impossibility of decorative milling low moisture resistance more weight compared to MDF the release of formaldehyde, harmful and even dangerous for the human body deformation under prolonged static loads over time, poor retention of fasteners need for edging |

| MDF | environmental Safety the ability to use almost any type of processing has some of the qualities of natural wood high impact resistance high moisture resistance perfectly smooth surface long service life the ability to perform decorative milling | high cost in comparison with laminated chipboard, chipboard at the moment there is not such a large selection of decorative coatings as for laminated chipboard |

Related article:

How the price of laminated chipboard depends on the size and thickness of the sheets

The designer, after the design of the cabinet, kitchen, etc. has been created, needs to cut the material, and for this it is necessary to know the dimensions of 16 mm chipboard sheets. By the way, the thickness of the laminated particle board is selected in accordance with the product design.

To say that there is a single standard for laminated particleboard sheets can only be a stretch. A standard sheet has dimensions of 2800 × 2070 mm.

The table below shows the standard dimensions of 16 mm chipboard, thickness, area and weight:

| Dimensions, mm | Thickness, mm | Area, m2 | Weight, kg |

|---|---|---|---|

| 2440*1830 | 16 | 4,7 | 52,1 |

| 2750*1830 | 16 | 5,03 | 58,7 |

| 2800*2070 | 16 | 5,79 | 59,8 |

| 3060*1830 | 16 | 5,60 | 65,3 |

| 3060*1220 | 16 | 3,73 | 43,5 |

| 3060*610 | 16 | 1,87 | 21,8 |

On average, the weight of 1 square meter of 16 mm laminated chipboard is 10.36 kg.

Popular thicknesses and applications

The table below shows what is the thickness of chipboard and where such plates are used:

| Thickness, mm | Scope of application |

|---|---|

| 8 | It is used for cladding walls, doors, decorative furniture elements, making transport boxes and packaging, as well as the bottom of drawers |

| 16 | It is used for the production of furniture, installation of internal partitions and subfloors |

| 18 | Used in the manufacture of cabinet furniture and as a base for flooring |

| 20 | Mainly used for sub-flooring |

| 22 | Used to make countertops, tables, kitchen sets and chairs |

| 25 | It is used for the production of doors, countertops, window sills and various load-bearing elements of commercial structures |

| 32 | All the above elements, but designed for high load |

| 38 | Used for the device of bar counters and kitchen countertops |

Where is chipboard used

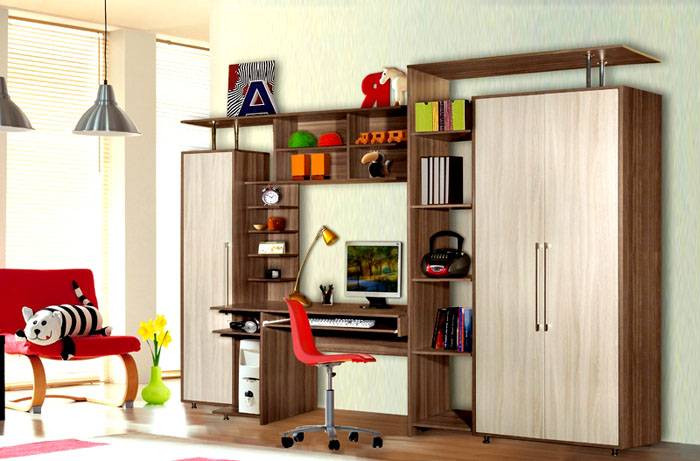

As already mentioned, laminated chipboard is mainly used for the manufacture of furniture.This is due to the fact that this material is durable, cheap compared to wood, and has a wide palette of colors and textures. Each type of furniture requires chipboard of a certain thickness and class.

Making a kitchen from chipboard

Laminated chipboard kitchen sets are the most popular and affordable option. This is largely due to the rich choice of colors and textures, well thought-out design and durability, subject to proper care.

The main advantage of laminated chipboard kitchens is their low cost. Despite its budget, this material has several features, namely:

Having decided to buy, order or make a kitchen from chipboard with your own hands, you first need to decide on the layout in order to know exactly how many lower and hinged modules are required and where to install them. It depends on this - whether a standard ready-made headset from the store is suitable, you will have to assemble a set of different modules, or you will need to order furniture according to an individual project. By the way, the latter option is the most optimal, and despite the fact that such a kitchen will cost more than a ready-made one, it will ideally take its place without leaving empty space.

Chipboard kitchens look great while new, but with improper care they quickly lose their appearance and become unusable. In order for any kitchen from laminated chipboard reviews, which in most cases are positive, to last a long time, you should adhere to a few simple rules for care:

The main thing is to properly care for the furniture and it will retain its original appearance for many years.

If you adhere to these rules, then the furniture will last for many years and retain its original appearance. In the photo, laminated chipboard kitchens do not look at all like budget models.

Attractive and affordable: laminated chipboard furniture

Not only kitchens are made of laminated chipboard. Since the material is very easy to process, you can make furniture from it yourself at home. For example, you can easily make your own chipboard beds. To do this, you just need a drill with a drill and nozzles, hex keys, screwdrivers and, of course, material. Drawings can be easily found on the Internet or made by yourself (if you have experience), and the material, cutting and cutting to the required size, can be ordered from specialized stores or firms. By the way, in addition to the bed, you can make a bedside table from chipboard, especially since 1-1.5 large sheets of material are enough for this, and build from the remains bookshelves or flowers.

In principle, for any piece of furniture, be it a medium-sized wardrobe, a standard laminated chipboard chest of drawers for 4 drawers, a desk and much more, just one sheet of "laminate" is enough. As already mentioned, drawings with dimensions can be easily found on the Internet or you can calculate everything yourself, especially since, knowing the dimensions of the sheet and its thickness, it will not be difficult.In general, do-it-yourself laminated chipboard furniture is not only an interesting and economically profitable activity, but also brings pleasure from the fact that you can make a unique and original thing that no one has.

Plumbing partitions from laminated chipboard for bathrooms

Relatively recently, sanitary partitions in home and public bathrooms were created from bricks, foam blocks or drywall... Such designs were time consuming and costly. At the moment, lightweight partitions that can be quickly installed have become an alternative to such partitions.

Modern plumbing partitions consist of a lightweight frame, sheet material and special fittings. The frame is usually made of anodized aluminum. Chipboard, tempered glass or plastic panels are used as a filler. Fittings are furniture handles, locks and hooks.

Chipboard is mainly used for partitions, since it is a durable material with a rich color palette and low cost.

Sawing and edging of chipboard

When creating furniture, you can't do without cutting the material. But in order for the product to turn out smooth, beautiful and without chips, certain experience and equipment are required. It is quite difficult to qualitatively cut a sheet of material at home due to its large size, but there are specialized stores and firms that cut chipboard according to the customer's size.

Of course, it is difficult to saw a large sheet with an ordinary jigsaw, but on the machine it is a completely different matter

Home cutting

It is possible to cut the "laminate" at home, but it is hardly possible to avoid chips, although it is possible to reduce their size and number. It is possible to cut the chipboard more or less efficiently at home if:

These tips will help to reduce the number of chips, but completely avoid them and make a perfectly straight cut line cannot be obtained without special equipment that only specialized companies can afford.

Video: how to cut the material without chips

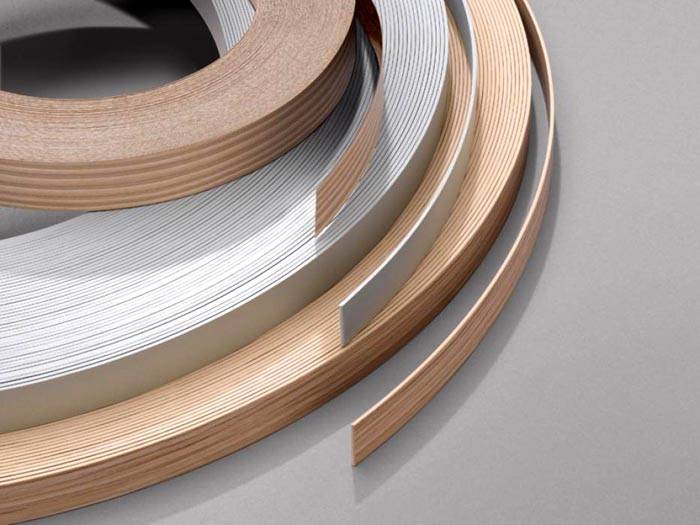

What is edging and why is it necessary

Edging is a mandatory application of a protective strip made of various materials to the ends of parts. The edge has several important functions:

You can make edging of chipboard with your own hands, and you can also order this operation at a specialized company that uses special edging machines for these purposes.

For edging, a paper (melamine) or PVC edge is used.At home, it is easier to work with a melamine strip that has an adhesive layer. The edge is applied to the end of the part, ironed with a hot iron or heated with an industrial hairdryer and rubbed with a bar wrapped in felt or cloth. Carefully remove the protruding edges of the protective strip (so as not to accidentally cut off the laminated layer) using a boot knife or the blunt side of the blade from a clerical cutter. After that, go "zero" along the cut marks, also trying not to touch the laminating layer of the board.

Furniture firms mainly use PVC edging and hand-held finishing equipment (special routers).

You can learn about the types of end edges from this video:

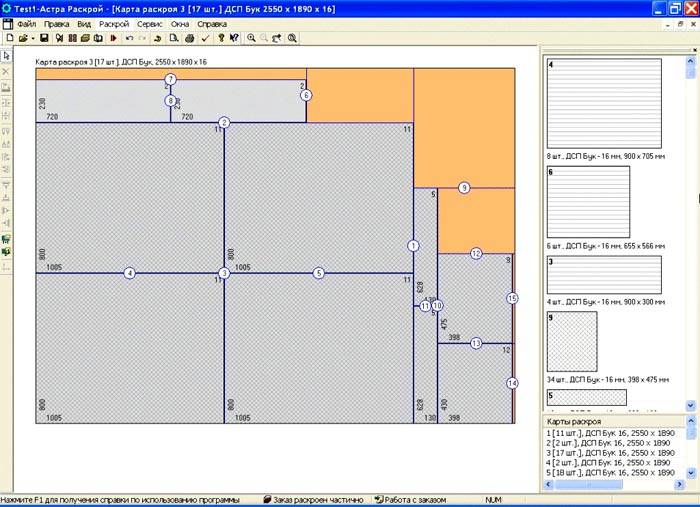

Chipboard cutting software and online resources

After the furniture project has been developed, the dimensions of all the necessary elements have been calculated and a detailed detailing has been drawn up, it is necessary to make a material cutting map. This is necessary for optimal placement of all parts on the plate, to facilitate the sawman's work and, most importantly, to minimize waste. If you order furniture from a company, the designer knows perfectly well what to do and can easily cut laminated chipboard to the size of customers, but when everything is done at home on your own, a special program is required.

There are several popular programs for cutting sheet or roll materials - Bazik-Mebel, Astra, Cutting and others. All these programs are paid, but you can also download "cracked" options, although there is a great risk of capturing a not very pleasant surprise on your computer, the elimination of which can cost more than paying for the purchase of licensed software. He has to buy a license only if the production of furniture is a means of earning for you, and for a single case you can make an online cutting of chipboard on the Internet, since there are plenty of such resources.

Now there are many specialized sites on the Internet where you can find drawings of any furniture with detailed detailing and a detailed description of the assembly process. There you can also find online calculators for cutting laminated chipboard.

By watching the video below, you can get an idea of how a material cutting map is made:

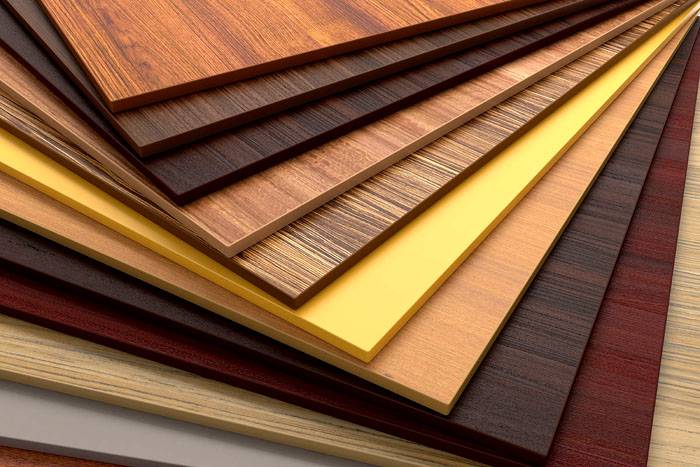

Chipboard color table: photo with names

As we said before, laminated particle boards from various manufacturers come in rich colors and textures. Below are the most popular laminate colors.

Laminated chipboard manufacturers

When buying a "laminate", one should take into account the class of material, its quality, manufacturer and that the seller must have all the necessary certificates. Among all of the above, one of the important elements is precisely the manufacturer, who is the guarantor of the quality and environmental safety of the chipboard purchased for the manufacture of furniture or other purposes. Below we propose to get acquainted with the most popular and leading manufacturers of laminated chipboard.

EGGER

The Austrian company Egger was founded in 1961. Initially, a rather modest family company, over time, it grew to one of the world leaders in the industry. High quality, an extensive catalog of Egger laminated chipboard colors and affordability were achieved thanks to the presence of our own facilities in seven European countries, including the Russian Federation.The boards are made from coniferous trees and meet European quality and environmental safety standards.

The demand for the company's products is growing every year. Reviews of buyers of products of this company note the high wear resistance of the material, excellent quality and the minimum content of formaldehyde resins. The leading supplier on the Russian chipboard market Egger - Basis, a company that works with leading manufacturers of panel material.

LAMARTY

The products of the Syktyvkar Plywood Plant successfully compete with foreign analogues. Laminated chipboard Lamarty is made from high-quality raw materials from coniferous and birch woods without foreign inclusions, has a certificate of environmental safety and excellent technical characteristics. The material has high wear resistance, is not afraid of moisture and high temperatures, is durable, environmentally friendly and retains its original appearance for a long time. Extensive catalogs of Lamarti laminated chipboard colors allow designers to create the most original projects.

Since 2012, the company has mastered the production of laminated chipboard of class E 0.5. The material fully complies with the highest EU requirements for formaldehyde content.

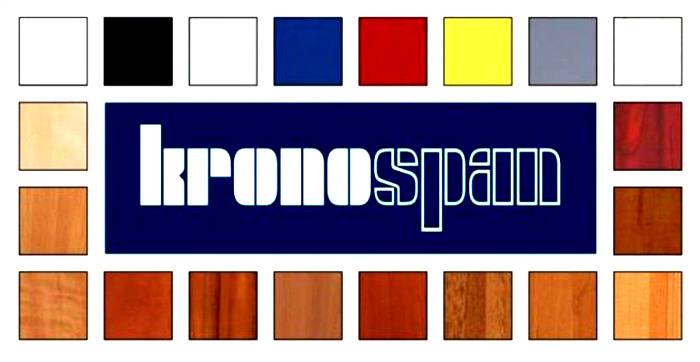

KRONOSPAN

Another company from Austria, which originated in 1897 in Salzburg at a small family sawmill. At the moment, the business activity of the firm extends to 24 countries around the world. Among the advantages of the products of this company, it is worth highlighting:

Russian laminate

The Russian Laminat company was founded in 1993 on the basis of a small particle board workshop, which was reconstructed and equipped with new Bison equipment. Today "Russian Laminate" is one of the leaders of the Russian Federation in this industry. The manufacturer has its own logging facilities, so there are no problems with the supply of raw materials.

The company is engaged in the production of high quality materials for the production of furniture:

In addition to the production of boards "Russian Laminat" is engaged in the production of components and accessories for the manufacture of furniture.

High-quality materials and a large number of colors allow designers to bring to life the most original projects

In the extensive catalog of colors of laminated chipboard "Russian Laminata" there are over 120 different decors of the laminated surface. The entire decor is divided into 3 groups, which include classic wood designs, fabric finishes and monochrome colors.

Furniture laminated chipboard produced by the Russian Laminat company is a rather profitable solution for those who are engaged in the production of cabinet and upholstered furniture. High quality material and a variety of decorative coating designs will satisfy even the most demanding customer.

Nevsky laminate

The company "Nevsky Laminat" offers its customers high quality laminated chipboard and environmentally friendly, while the cost of the material compares favorably with foreign analogues. The laminated boards of this Russian manufacturer are resistant to moisture and mechanical damage, and are also distinguished by wear resistance and a rather long service life.

In the catalog of laminated chipboard "Nevsky Laminat" there is a large selection of wall panels, glossy boards and countertops that have high strength characteristics and excellent appearance. The variety of colors allows designers to design the most original furniture designs.

Internet addresses of popular chipboard manufacturers

| Company | Products | Official site |

|---|---|---|

| Egger | Furniture, laminated chipboard, fittings, building materials, floor coverings | https://www.egger.com/shop/ru_RU |

| Lamarty | Chipboard | http://www.lamarty.ru/lamarty |

| Kronospan | Chipboard, MDF, edges and fittings | http://kronospan-express.com |

| "Russian laminate" | Chipboard, MDF, edges and fittings | http://www.ruslaminat.ru/zavod-ldsp |

| "Motherland's bins" | Chipboard, chipboard, fiberboard, MDF, DVPO, profile, edge, plywood | http://www.zakroma.spb.ru |

| LLC "ShKDP" | Chipboard, chipboard, MDF | http://www.skdp.ru |

| "Monzenskiy Woodworking Plant" | Chipboard | http://www.pm96.ru |

| "Credo" | Board materials, accessories, edging materials | http://www.kredo-m.ru |

| "Nevsky laminate" | Laminated boards, countertops, edging materials | http://dspnd.ru |

The cost of material from different manufacturers

When deciding to make furniture on your own at home, it is best to buy chipboard with a saw cut, especially since almost all companies selling board material provide such a service.

| Company | Chipboard size, mm | Average cost of 1 sheet of standard size, rub. |

|---|---|---|

| Kronospan | 2800x2070x16 | 1800-3100 |

| Egger | 2800x2070x16 | 1600-3105 |

| Russian laminate | 2800x2070x16 mm | from 3500 |

| Nevsky laminate | 2440x1220x16 mm | 4900-7000 |

| Monzensky Woodworking Plant | 2750x1830x16 | from 3350 |

| LAMARTY | 2800x2070x16 mm | 1600-3105 |

Before you buy laminated chipboard for furniture, the price per sheet must be carefully correlated with the safety class, thickness, decor and manufacturer. It is worth considering these characteristics and already on the basis of this make a choice in favor of one or another manufacturer.

A few final words

Making furniture requires not only sufficient experience, good tools and design, but also high quality, safe material. It is possible to purchase high-quality laminated chipboard that meets all the requirements of European standards only from trusted manufacturers and suppliers. Foreign manufacturers offer high-quality material, but you should not overpay only for a well-known brand, because domestic companies produce laminated plates that are not inferior in characteristics to imported counterparts, but are cheaper.