Why do you need tile grout

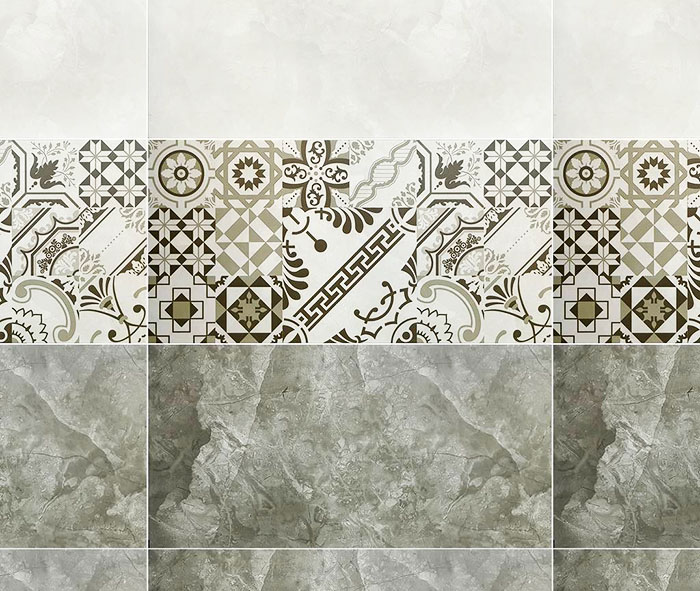

Ceramic tile (tile, porcelain stoneware, glass mosaic etc.) is a very popular finishing material due to its practicality, durability and resistance to moisture. However, all these benefits can be nullified by improper use. The ingress of moisture into the adhesive layer and the ends of the tile is one of the main reasons for the cladding to peel off from the base and the appearance of chips. In addition, high humidity combined with warmth is an optimal breeding ground for mold, fungus and other pathogenic organisms. To prevent negative consequences, it is imperative to grout tile joints with special materials (fugue). This article will describe the various compositions of grout, their properties, scope and application technology.

Any tiled surface, regardless of the type of finishing material, needs grouting

PHOTO: stroy-podskazka.ru

The content of the article [Hide]

Appointment of grout for tile joints

Tile grout has two main functions:

One of the functions of tile grouting is decoration, therefore special attention is paid to the choice of color

PHOTO: stroy-podskazka.ru

Grouting tiles: classification by composition

On the market of building and finishing materials, there is a wide range of grouting, differing both in composition and cost. Manufacturers offer the following varieties based on:

The main operational characteristics and advantages of the presented materials need to be considered in more detail.

Cement based grout has a limited range of colors. However, using a white base, you can color it yourself using special pigments.

PHOTO: stroy-podskazka.ru

Cement

Cement grouts are among the most common and affordable. The composition includes high-quality white or gray Portland cement of the M600 brand and above with fine fillers. As additives, many manufacturers use:

When sealing wide joints in a cement binder, it is allowed to add washed and sieved sand

PHOTO: stroy-podskazka.ru

Cement-based grouts are sold in the form of dry mortars. It is recommended to use it for finishing technical rooms with a low load. The optimum joint width is 5 mm. If the joint is wider, it is recommended to add sifted sand to the grout yourself.

Table 1. Cement grout

| Advantages | disadvantages |

|---|---|

| Affordable price | Mediocre moisture resistance |

| Low frost resistance | |

| Ease of preparation | Low resistance to mechanical stress (when cleaning, it is quickly removed from the seams) |

| Difficulties in application, scratches on the surface of glazed tiles |

Polymer

Polymer grouts are characterized by higher performance parameters than cement ones. As a rule, they are sold as ready-to-use formulations in buckets or in special tubes. However, there are also dry mixes.

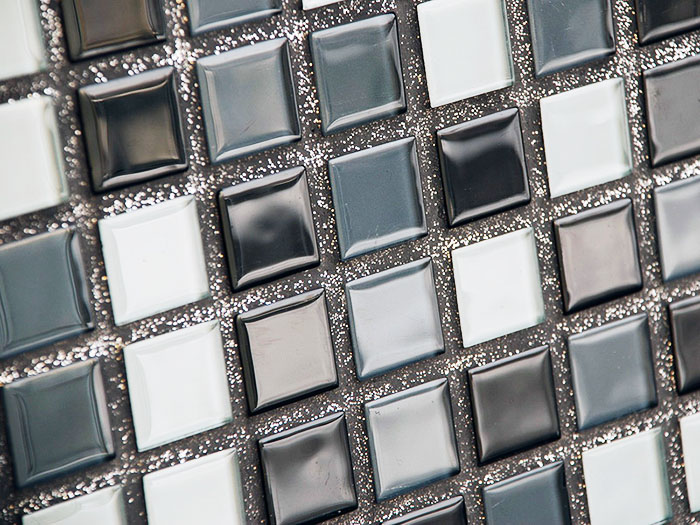

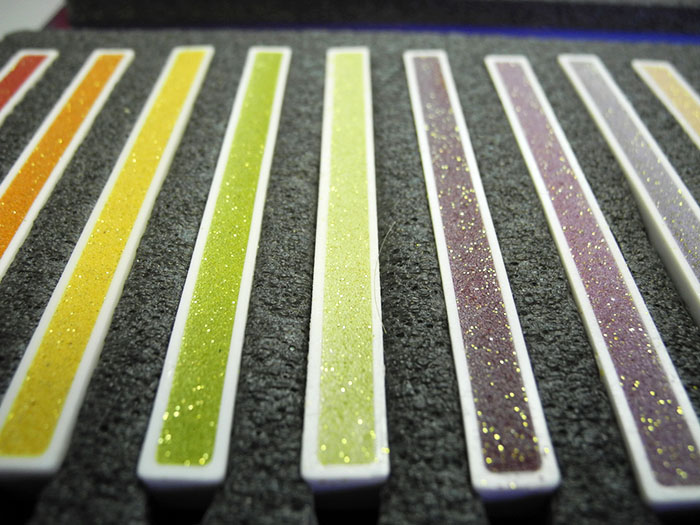

When mixing epoxy grout with metallized glitters, the joints acquire a special visual effect

PHOTO: stroy-podskazka.ru

Table 2. Epoxy grout

| Advantages | disadvantages |

|---|---|

| High performance and decorative characteristics: strength, wear resistance, moisture resistance | High price |

| High adhesion to all types of tiles, including metal, stone and glass | Preparation of the composition requires great precision |

| Long service life up to 50 years | Short period of use |

Related article:

When filling wide joints (more than 5mm), it is recommended to mix with finely dispersed quartz sand

PHOTO: stroy-podskazka.ru

Table 3. Polyurethane grouts

| Advantages | disadvantages |

|---|---|

| Moisture-repellent effect and resistance to most household chemicals will ensure easy cleaning | Quite high cost |

| High elasticity in combination with fine base mortar filler allows filling the narrowest joints | |

| The duration of the life span of the composition | Do not use chlorine-based products for cleaning |

| The remains of grout can be easily removed from the surface of the tile |

Acrylic grout is sold in tubes and tubes as a ready-to-use, already painted composition

PHOTO: stroy-podskazka.ru

Table 4. Acrylic grout

| Advantages | disadvantages |

|---|---|

| Versatility | High price |

| Ease of use | Low resistance to mechanical damage |

| Absolute tightness | Limited color palette |

| Resistance to household chemicals |

Excellent for cladding that is constantly in contact with water and subject to thermal deformation

PHOTO: stroy-podskazka.ru

Table 5. Latex grout

| Advantages | disadvantages |

|---|---|

| High elasticity, does not crack under mechanical and thermal effects | High price |

| UV resistant | |

| Not subject to chemical and biological corrosion | It is necessary to immediately remove its remnants from the surface of the tile, otherwise cloudy traces will form |

| Filling of wide joints without fillers is allowed |

Transparent silicone sealant can be used both as a base grout and as a repair compound on a colored base

PHOTO: dekoriko.ru

Table 6. Silicone grouts

| Advantages | disadvantages |

|---|---|

| Ease of application | High price |

| Minor shrinkage parameters | Exposure to high temperatures is not allowed |

| High adhesion to almost all materials |

Furan

Furan resin based grouting materials have very high performance parameters. They are extremely resistant to any type of chemical attack, including strong acids and alkalis. They are produced both in pure form and in mixtures with Portland cement and latex. The most common brands are intended for outdoor use, in technical rooms they are black. They are rarely used for household needs.

Video about the main characteristics of grout and the features of their use

Color selection features

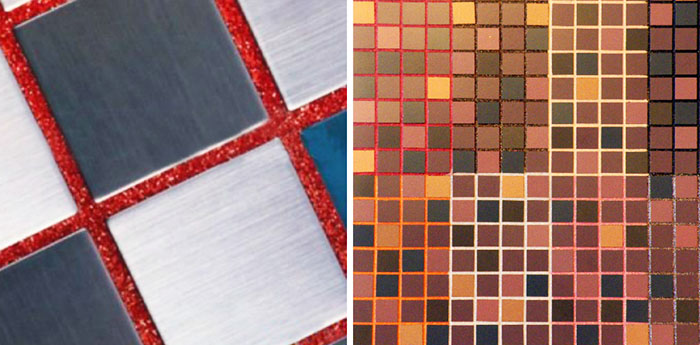

As mentioned, one of the main tasks of grouting is decorating the tiled surface. For this, various colors are used, in harmony with the background color or tile pattern:

The graphite color of the fugue is combined with different tones of the green color palette

PHOTO: modernplace.ru

When using ceramic cladding imitating wood, the tile joint should be minimal and filled with a joint that is as close as possible in color to the general background

PHOTO: youtube.com

Main manufacturers

As a rule, the grout is produced by the same manufacturers as the tile adhesive. Therefore, when choosing, you need to focus specifically on their brands.

Related article:

The color palette of the fugue collection based on Litokol Litochrom epoxy resin

PHOTO: laraceramica.com

Grout for joints - choose the right composition

The building materials market offers a huge selection of grouts, the cost of which can vary significantly. To select the correct composition, a number of characteristics must be analyzed:

- Shrinkage coefficient - shows the decrease in the volume of the fugue upon drying. Not only the required amount of grout depends on this indicator, but also the maximum joint width that can be processed without cracking.

- Adhesion - strength of adhesion to the surface. You should pay attention to the materials recommended by the manufacturer: ceramic tiles, porcelain stoneware, clinker, majolica, bicottura, etc.

- Time of use of the ready-made solution. For inexperienced craftsmen, it is better to choose ready-to-use formulations with a long life span.

- Performance characteristics: water resistance, frost resistance, resistance to mechanical damage, resistance to chemicals, resistance to biological corrosion. The combination of these parameters is selected depending on the field of application: floor, wall, for outdoor or indoor use.

Table 7. Grout characteristics

| Requirements | Application area | ||

|---|---|---|---|

| For interior work | For outdoor work | ||

| For floor | For walls | ||

| Strength | + | - | + |

| Water resistance | + | - | + |

| Frost resistance | - | - | + |

| Wide operating temperature range | - | - | + |

| Resistance to chemicals | + | + | - |

| Resistant to biological corrosion | + | + | + |

Instructions for self-grouting of tile joints

The grouting process itself does not present any particular difficulties, adhering to simple rules, you can completely perform it yourself. To do this, you need to purchase a minimum set of tools:

You can purchase a special knife for cleaning seams - with replaceable blades, or you can use an ordinary kitchen knife.

After the end of the tile laying process, the technological pause, depending on the type of glue used, can be from several hours to a day. After that, you can start grouting tile joints.

Table 8. Instructions for self-grouting of tile joints

| Illustration | Action Description |

|---|---|

| Seams are thoroughly cleaned of the glue that has filled them with a scraper or knife. It is better to use a special tool, as it eliminates the possibility of damaging the face of the tile. The crushed glue mixture is swept out with a narrow paint brush | |

| If necessary, the trowel mixture is diluted with water. At the same time, the dry construction mixture is added to a container with pre-measured water, and not vice versa. The amount of liquid must meet the manufacturer's requirements indicated on the package. The fugue is thoroughly mixed until a homogeneous mass is obtained. | |

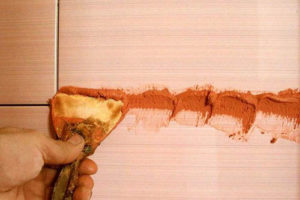

| Using an ordinary household spray or brush, the tile joint is moistened with water. The grout is applied with sharp short strokes across the joint. At the same time, you must try to squeeze it as deeply as possible into the space between the tiles. | |

| After the seam is completely filled, the spatula is cleaned and carried along the seam, collecting the excess fugue | |

| Until the grout on the tile surface is completely dry, it is removed with a sponge or damp cloth. |

Video instruction for grouting tile joints

Grout cracking and how to deal with them

Sometimes, after drying, the grout in the joints, especially wide ones, cracks. There may be several reasons:

To avoid cracking the fugue, you must strictly adhere to the following rules:

conclusions

Despite the apparent simplicity, grouting tiles requires careful adherence to the instructions. Otherwise, the formation of mold and peeling of the cladding cannot be avoided. In addition, we strongly recommend purchasing a fugue only from trusted manufacturers.

If the article turned out to be useful to you, share it with your friends and be sure to leave comments.