Flexible shingles: DIY installation with step by step photos

If flexible shingles are chosen as the roofing material, do-it-yourself laying can be done by a home craftsman without helpers. Do not confuse flexible roofing with soft roofing, which is presented as roll materialsused for flat roofs.

The content of the article [Hide]

Overview, types, characteristics, pros / cons

Due to the extremely simple design that flexible tiles have, do-it-yourself laying is not difficult, even for a non-professional. This roofing material is produced in the form of shingles:

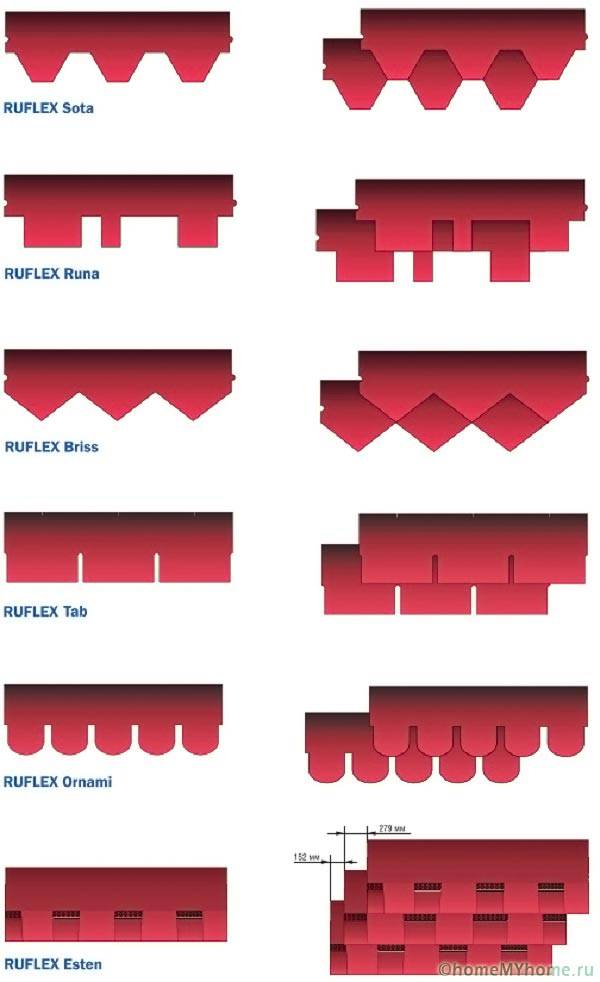

Shingles from different manufacturers do not have the same dimensions (medium format 1 x 0.35 m), 3 mm thick. There are several types of tile pattern:

The color of the shingles can be multi-chrome or monochrome, different in each box. Therefore, before stacking, all available material from different boxes is mixed in random order. Flexible roof tiles from Shinglas, Tegola or any manufacturer with a 3D effect have the maximum artistic value. The self-adhesive layer does not ensure the reliability of fixing the shingles, therefore the roof is additionally attached to the lathing with nails.

Video: how to choose flexible shingles

Related article:

Preparatory work

If flexible tiles are included in the roof project, do-it-yourself laying should begin with determining the number of facing, additional, consumables. Make sure that the bottom often of the roofing pie is assembled in accordance with the requirements for this coating.

Payment

Before purchasing the required number of shingles, slats, single carpets, skates, other additional elements, fasteners, a calculation is required to ensure a supply of materials. The approximate consumption is:

The valley carpet has a stone powder similar to shingles, abutment strips, cornice overhangs, pediment ones are made of special steel. On the websites of leading manufacturers, there are mandatory calculators for calculating the amount of materials for single, multi-slope, hip, hip, mansard roofs.

Tools

For laying the roofing material in question, a hand tool that is present in the arsenal of a home craftsman is sufficient:

Stacking theory

For the convenience of working at a height, the shingles have a small format. They are stacked from the overhang to the ridge with a ledge, so that each upper row overlaps the lower one. Endows, nodes of passages chimneysThe ventilation pipes are processed first. Then the cornice, pediment strips are fixed, the gutter brackets are attached. After that, it remains to fill the surfaces of the slopes with shingles, cutting them in width and length as needed.

Installation technology

If you are laying flexible tiles with your own hands without helpers, it is enough to follow the technology below in order to avoid mistakes, reduce cut waste, and achieve the maximum possible operational resource.

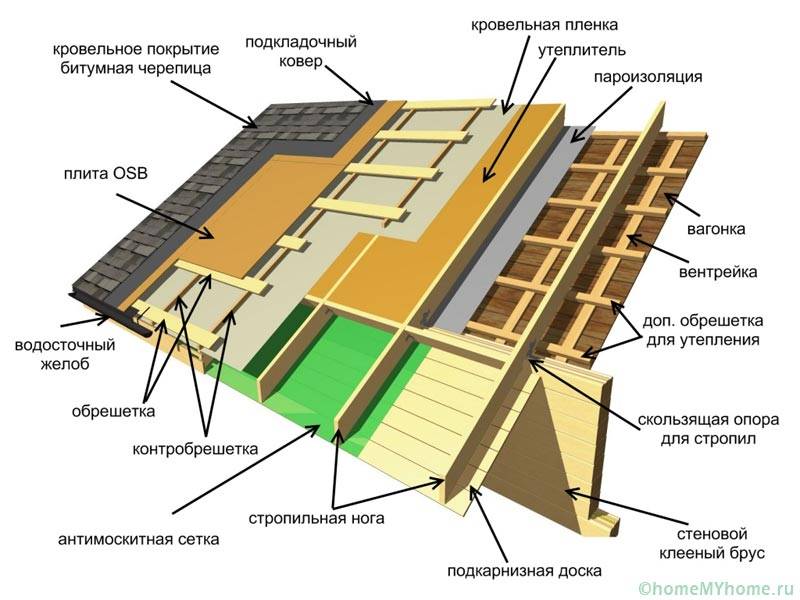

The roofing cake must be prepared accordingly:

Substrate

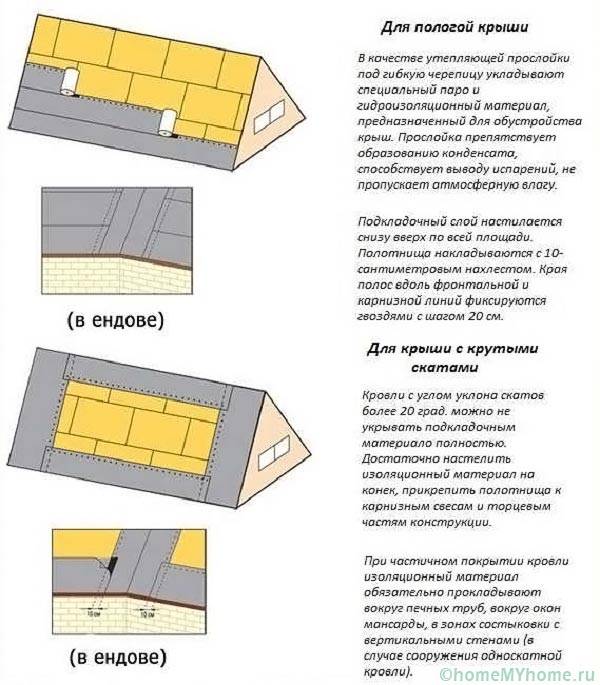

The lining carpet with a slope of 12 - 18 degrees is created solid. For this, the valley is pasted over with the OS HP hydro-barrier vertically (obliquely), overhangs at the cornices with the same material horizontally. The roll material of the lining carpet is glued to the crate with mastic in horizontal stripes from the bottom / up.

The width of the launch of the hydro-barrier for each slope in the valley is 0.5 m. The sheets of the underlay carpet have an overlap of 15 cm in adjacent rows and 10 cm when increasing the length in the vertical direction. The frequency of fixation with nails is 25 cm, additional coating with mastic is made in the overlap.

Installation of planks and gutters

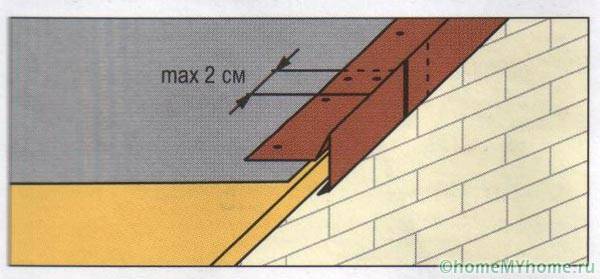

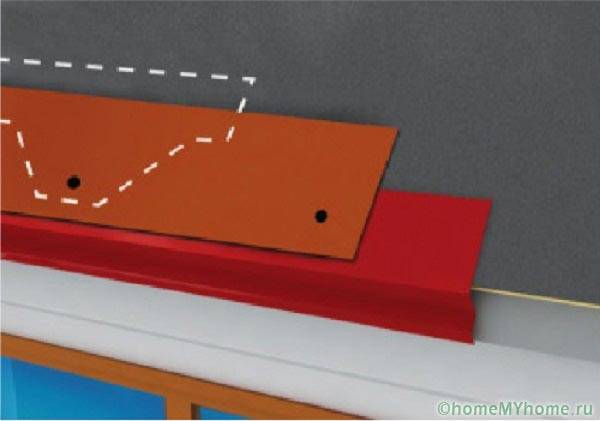

Eaves, gable steel slats are required to reinforce these roof elements. In these areas, one edge of the shingles does not have an overlap, therefore, the likelihood of scoring, loosening during wind loads, and heavy rainfall increases. Metal strips increase the spatial rigidity of the lathing, they are mounted with nails (15 cm pitch + checkerboard pattern) with an overlap of 3 - 5 cm.

Depending on the design and layout of the gutters at the eaves overhang, at the same stage, brackets can be attached to the crate or eaves strips, on which the gutters will be hung out.

Facing stingrays

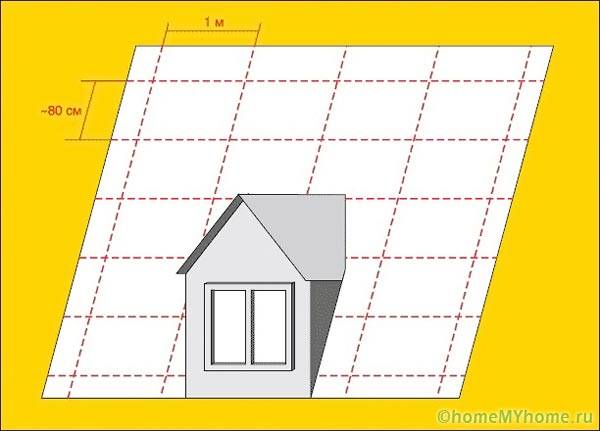

To have the maximum operational resource of the flexible tile, laying the shingles with your own hands begins with the marking:

The resulting mesh allows you to control the location of the sides of each shingle in a row, adjust as needed. Particularly relevant are the markings for roofs with dormers, dormers, chimneys, and ventilation pipes.

Shingle mounting technology will include several stages:

The nails should be placed perpendicular to the slope of the slope so that the head presses the material parallel to it, without distortions. It is not necessary to recessed the heads of the hardware. The punching scheme is present on the manufacturer's box, since it differs depending on the model of the shingles, the slope of the roof.

In the absence of a factory self-adhesive layer, the shingles are coated on the reverse side with mastic 10 cm wide from the upper edge. For the normal release of water with pediment strips, the shingles are cut 2 cm from their edge.

Junction nodes

Depending on the configuration of the roof, ridges (ribs formed by adjacent hip slopes by analogy with a ridge), fractures (conjugation of slopes on one side houses in the attic roof), valleys (internal corners at the junctions of the L-shaped roof, dormer).

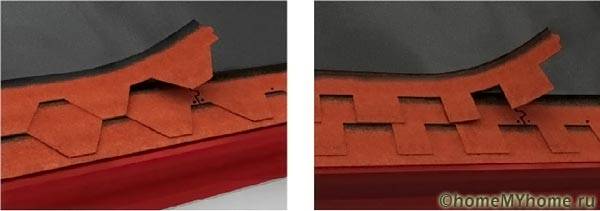

There are two options for decorating the valleys:

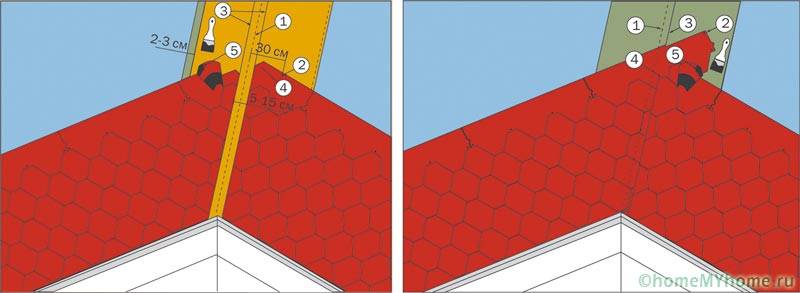

Adjacencies (to walls, parapets, other structures) are made using triangular slats ("glazing beads") nailed in the corners of the mates. To do this, a 50 x 50 mm timber is dissolved, the surface of the wall, to which the roof is adjacent, is pre-leveled with plaster or putty. Then, on top of the shingles, a piece of valley carpet 50 cm wide is glued onto the mastic with a launch of 30 cm on the wall.

It is better to arrange chimneys, ventilation pipes with special ceramic, steel additional elements. The shingles are adjacent to them or are overlapped from above.

Related article:

Conclusion

Thus, taking into account the above nuances, shingles can be assembled on their own alone. All manufacturers print on boxes or complete the roofing material with instructions that take into account the peculiarities of a particular shingle modification.

Video: shingles: DIY laying