Projects of houses from foam blocks: high-quality construction at no extra cost

Building a house is not an easy task. It is necessary to approach its solution thoroughly. Like any global construction site, building a house begins with its project. Today the editors of homemaster.techinfus.com/en/ decided to help you with this task and have selected, in our opinion, the most interesting projects of houses from foam blocks, which will allow you to build your own home quickly and without unnecessary moral and financial sacrifices.

To imagine your dream home in advance, the easiest way is to contact a special workshop, where, taking into account your wishes, specialists will create a voluminous project

The content of the article [Hide]

- 1 What sections are included in the projects of houses and cottages from foam blocks

- 2 Advantages of ready-made projects, making individual changes

- 3 What factors are taken into account in the individual design of houses from foam blocks

- 4 Overview of projects of houses from foam blocks with a layout

- 5 Technology for the construction of a private house from foam blocks

- 6 How much does it cost to build houses from foam blocks - an overview of prices, taking into account the specifics of the project

- 7 Video of the process of laying foam concrete blocks

What sections are included in the projects of houses and cottages from foam blocks

The project is the foundation of any home. The result of all work depends on how competently and clearly it will be drawn up. And in general, the quality and convenience of life for the whole family. Complete house project from foam concrete will help to calculate not only the volume of material purchase, but also the main stages of work and their sequence. It should be remembered that without it it will not be possible to arrange the finished building in accordance with the current norms of domestic legislation. The project is necessary to obtain official permits, high-quality performance of individual technological operations.

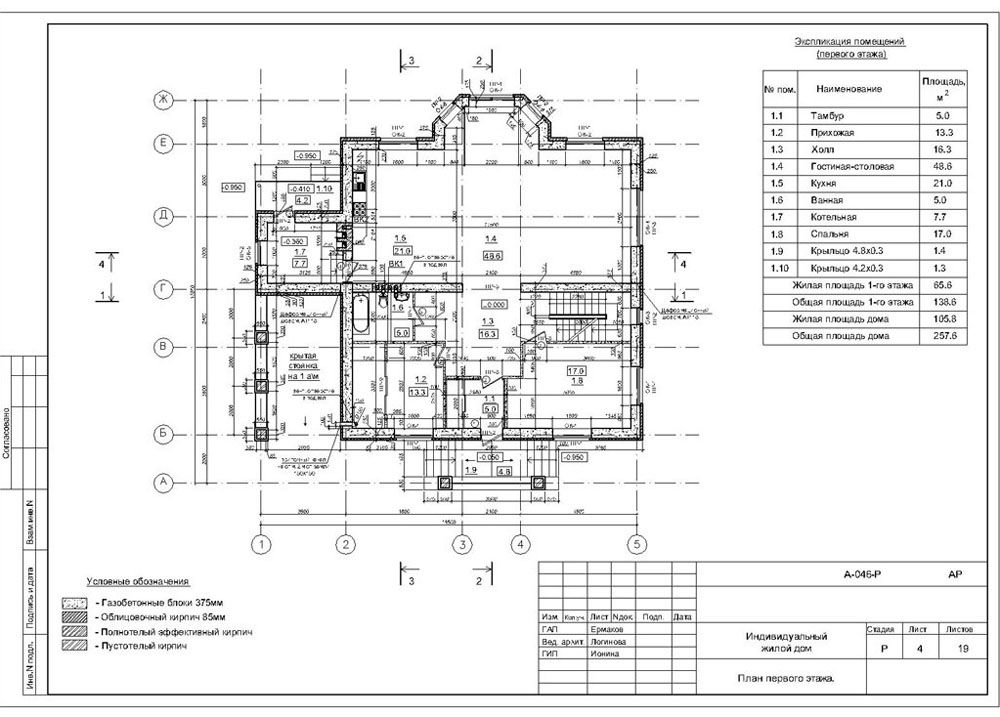

Let's analyze the sections of a typical house project.In the first section, general parameters typical for a typical structure are indicated. Dimensions of premises, location of door and window blocks. Here are also given:

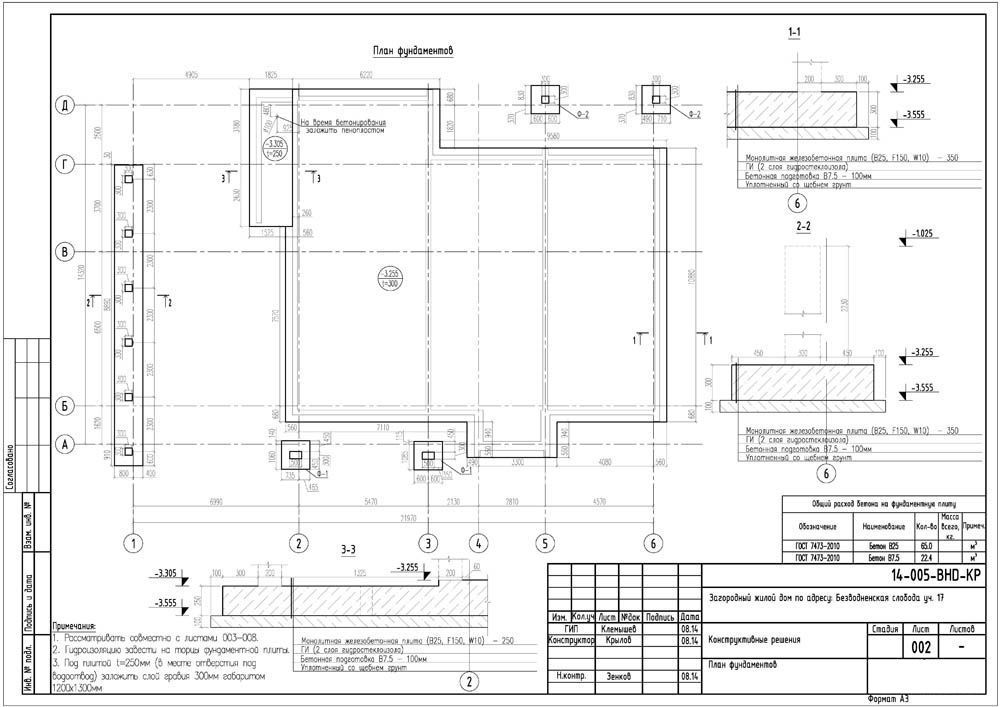

In the next block, the so-called design section, you can familiarize yourself in more detail with the individual parts of the structure: foundation, overlappings, flights of stairs, roof. Here are the materials, individual components. This section contains formulas and calculation of the structural strength of your home.

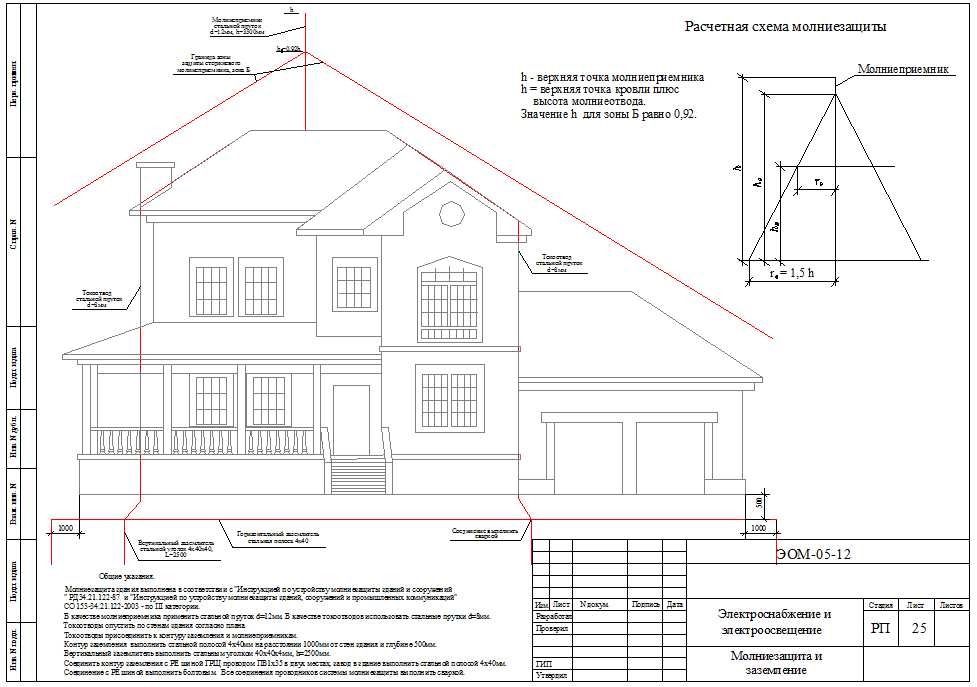

In the engineering block, descriptions of the systems are placed:

The next block reflects: cubic capacity, thermal conductivity of walls, other technical and operational indicators. Complex and non-standard technological methods and solutions are described separately. The authorship of the developers is indicated, copies of the licenses are attached.

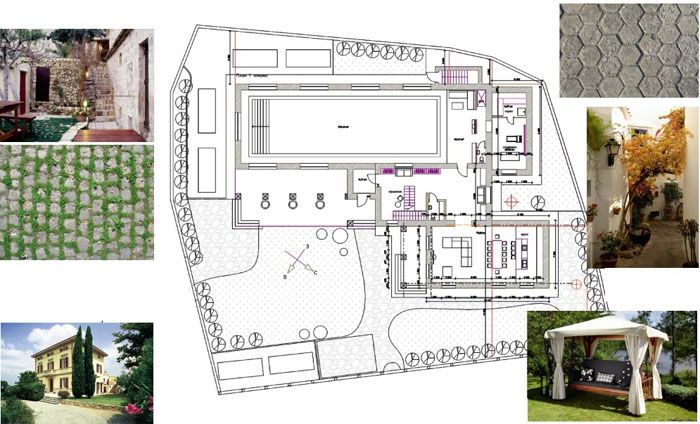

For clarity, "dry" drawings are accompanied by visual graphics. The photographs in the example demonstrate proposals for the creation of footpaths, arrangement of recreation areas.

Advantages of ready-made projects, making individual changes

In computer databases, there are hundreds of ready-made projects of houses from foam blocks. Therefore, you can quickly find the right option. Note the benefits of this solution:

The following list contains the changes that are made at the request of the customer in the projects of houses from foam blocks:

Partitions that do not function as a load-bearing frame are also moved. Any qualified corrections must not violate building codes. The price of finished projects of one-story and other houses made of foam blocks is much cheaper compared to preparing a full package of documents from scratch. As shown above, rapid, dramatic changes are permissible. They cover a wide range of potential needs. According to individual technical specifications, exclusive buildings are created, unique engineering problems are solved.

What factors are taken into account in the individual design of houses from foam blocks

Building materials in this category are created from a building mixture based on cement... Using different technologies, they provide a porous structure. Shapes or sawing large pieces are used to make blocks with the desired dimensions. The advantages of such products in comparison with traditional materials are obvious:

Large dimensions speed up the construction process. Suitable for size adjustment hand saw or a suitable power tool. The disadvantages listed below are given taking into account domestic specifics:

- Foam concrete blocks are inferior in strength to similar products made of ordinary concrete.

- It takes 20-30 days to be ready for use at low humidity and high enough temperature. Insufficiently responsible producers violate this rule.

- To obtain an even distribution of pores, it is necessary to apply quality technological processes.

- The natural shrinkage process can cause deformations of up to 1-3 m for each running meter of the building. In some situations, you have to pause up to 2.5-3 months before applying finishing decorative coatings.

The figure explains the simplicity of the individual techniques. Careful selection of the manufacturer is recommended to avoid problems during operation. The simplest check of the uniformity of the structure can be done visually by splitting the test block. Quality pores are of equal size. If the shade is too light, the amount of cement may not correspond to the norm. The density is specified by weighing the product in standard sizes.

Related article:

Seismic activity and geological features of the area

When building a private house from foam blocks, experts take into account the load capacity in conjunction with the insulation characteristics. For division into groups, use the density (kg / m³):

- The range 200-600 is suitable for creating layers of heat and sound protection.

- With values from 600 to 1000, the products can be used in places with limited loads (interior partitions).

- Products with a higher density are used in solid walls and load-bearing structures.

The stability of buildings is assessed as a whole. Total weight is essential. Below is an example for a two-story building.

| Materials | Weight, t | |||

|---|---|---|---|---|

| Contour walls | Internal walls and partitions | Total | Horizontal impact (seismic) | |

| Brick | 92,5 | 85 | 177,5 | 71 |

| Foam concrete | 45 | 42,5 | 87,5 | 35 |

The tests carried out in 2010 (TsNIISK named after V.A.Kucherenko) proved the possibility of using foam blocks with a density of 500 kg / m³ (concrete B3.5) for laying load-bearing walls in earthquake-prone regions. Of course, you need an accurate design calculation.

The reduction in weight implies a corresponding reduction in the foundation requirement. On stable soils, it is sufficient to use the usual belt structure with a deepening below the freezing level. The best stability will be provided by a monolithic (slab) base. But in this case, the amount of concrete, reinforcement and the total cost increases significantly.

Climatic conditions and the need for energy saving

The thermal resistance of the outer walls has been calculated for individual regions, which provides good protection against low outside temperatures. At the same time, it makes it easier to maintain comfortable conditions in the summer. The exact figures are given in SNiP "Thermal protection of buildings".

The calculation can be done using the formula:

T = C × Kwhere

Then all that remains is to select a suitable standard product with a small margin, which will help to compensate for extreme climatic conditions. The data in the table will be useful for a comparative analysis of different building materials. Pay attention to the column with thermal conductivity.It clearly demonstrates how you can save significant money during operation when choosing a house project from foam blocks.

| Construction Materials | Thermal conductivity, W / m × ° C | Density, kg / m³ | Vapor permeability, mg / mh × Pa |

|---|---|---|---|

| Foam blocks | 0,11-0,45 | 300-1200 | 0,25-0,11 |

| Reinforced concrete products | 1,8 | 2400 | 0,03 |

| Expanded clay concrete screed | 0,8 | 1800 | 0,09 |

| Pine bar (measurements along the grain) | 0,29 | 500 | 0,35 |

| Clay brick with voids | 0,5-0,6 | 1200-1600 | 0,17-0,14 |

| Silicate brick | 0,8 | 1800 | 0,11 |

| Fiber insulation materials (glass wool, etc.) | 0,05-0,06 | 50-120 | 0,5-0,3 |

| Polyurethane foam boards | 0,04-0,05 | 40-80 | 0,05 |

| Fiberboard, chipboard | 0,07-0,13 | 200-600 | 0,24-0,13 |

| Drywall | 0,19-0,38 | 800-1200 | 0,075 |

| Steel parts | 58 | 7800 | - |

Budget, individual customer preferences, formulation of consolidated requirements

The algorithm given below will help form the requirements for a suitable project of a foam block house without errors:

- Examine the land. Geological data will help determine the characteristics of the foundation. What matters is the location of the building relative to the entrance, cardinal points.

- Consider carefully the general plan with other buildings to choose the appropriate area / number of storeys for the main building.

- When defining with general characteristics, consider the need for premises, taking into account a sufficiently long time period (15-20 years).

Complex architectural forms, special design, bay windows, balconies, and other additions increase the cost of the project. The costs increase with the improvement of the insulation parameters. However, we must remember that such investments, together with the use of high-quality materials, will pay off many times in the future. Therefore, the correct economic calculation is made for a period of up to 30 years or more, taking into account current costs. Finished projects of houses from foam blocks are remodeled inexpensively using the following techniques:

- Mirroring drawings will allow you to change the position of rooms relative to parts of the world as needed.

- It is enough just to change the place of docking of the outbuildings (veranda, garage, winter garden).

- By transferring the openings to the front, the building can be moved closer to the border of the land plot.

Overview of projects of houses from foam blocks with a layout

It is convenient to purchase projects of houses from foam blocks with a complex of construction work from one organization. The turnkey price does not change with the appropriate contractual arrangement. The customer receives reliable general guarantees. Control of performers is simplified and their responsibility is increased. The total cost is less than choosing multiple contractors. The typical solutions presented below can be used for the construction of buildings on their own.

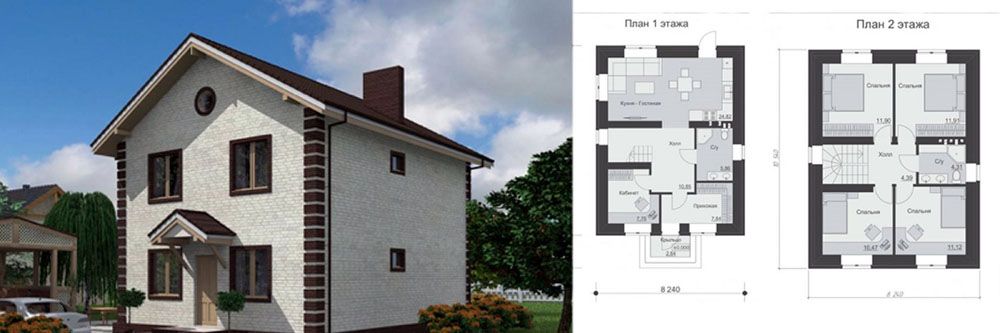

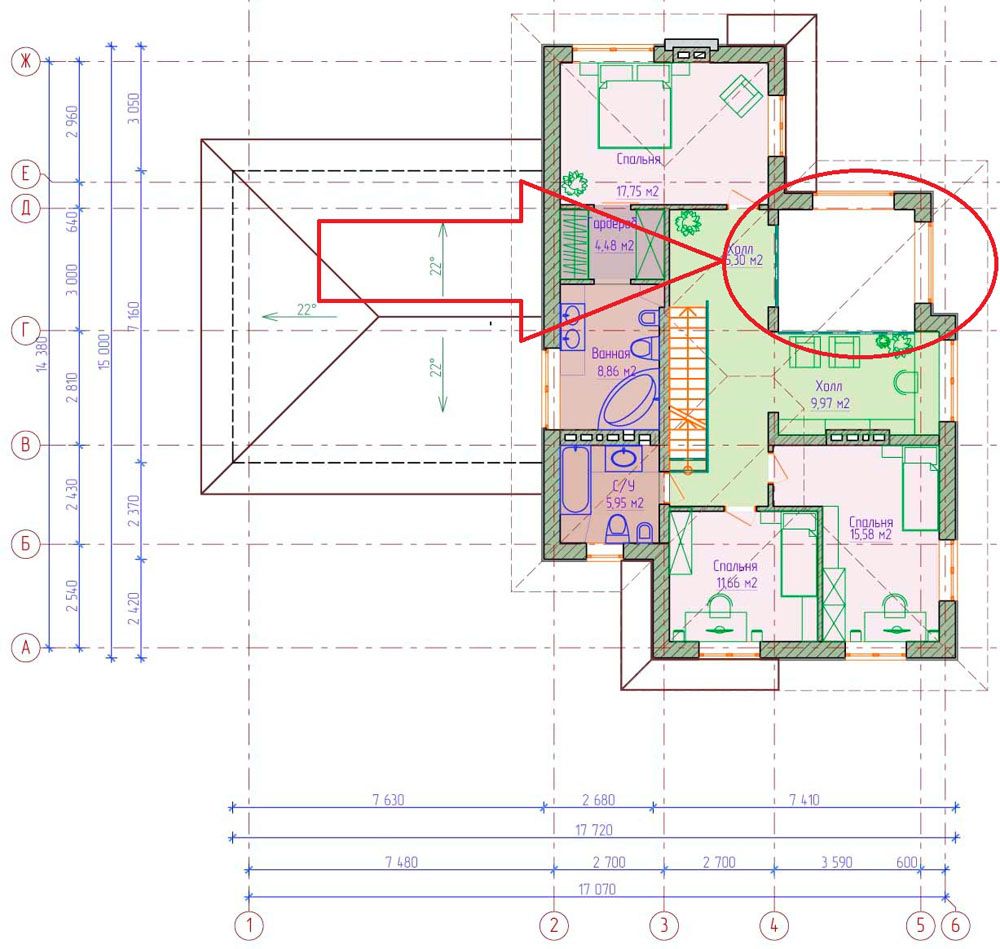

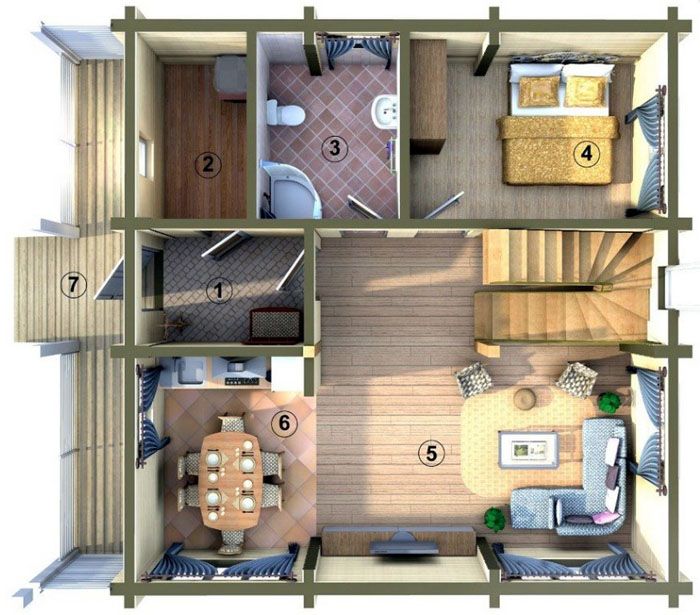

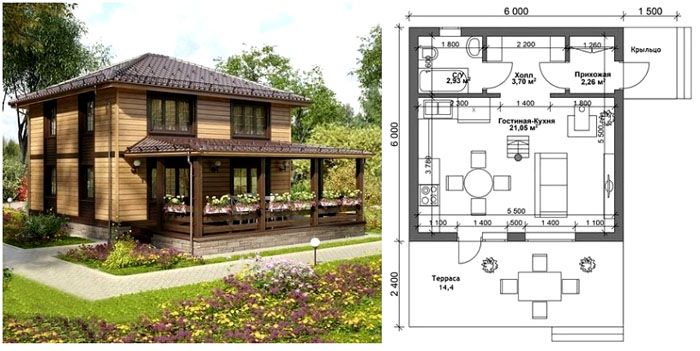

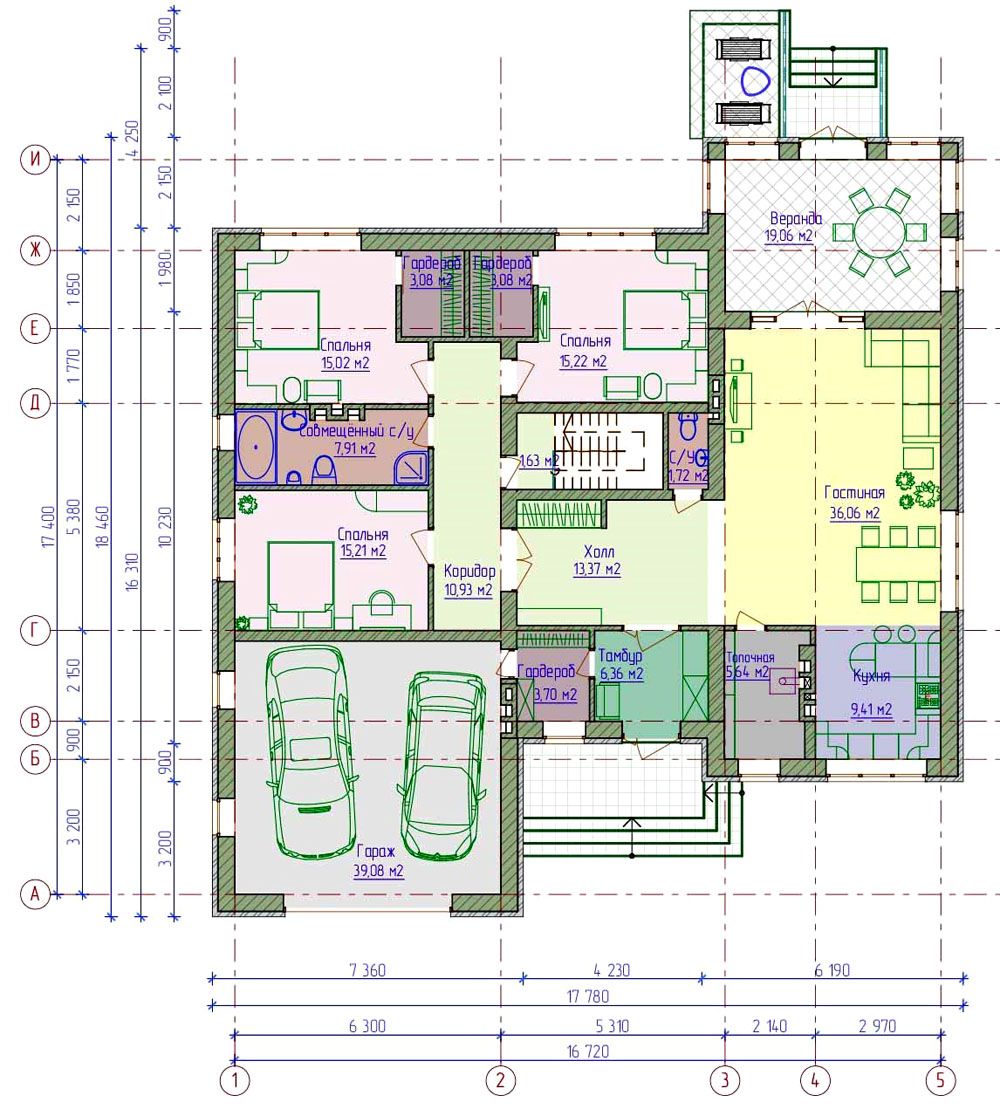

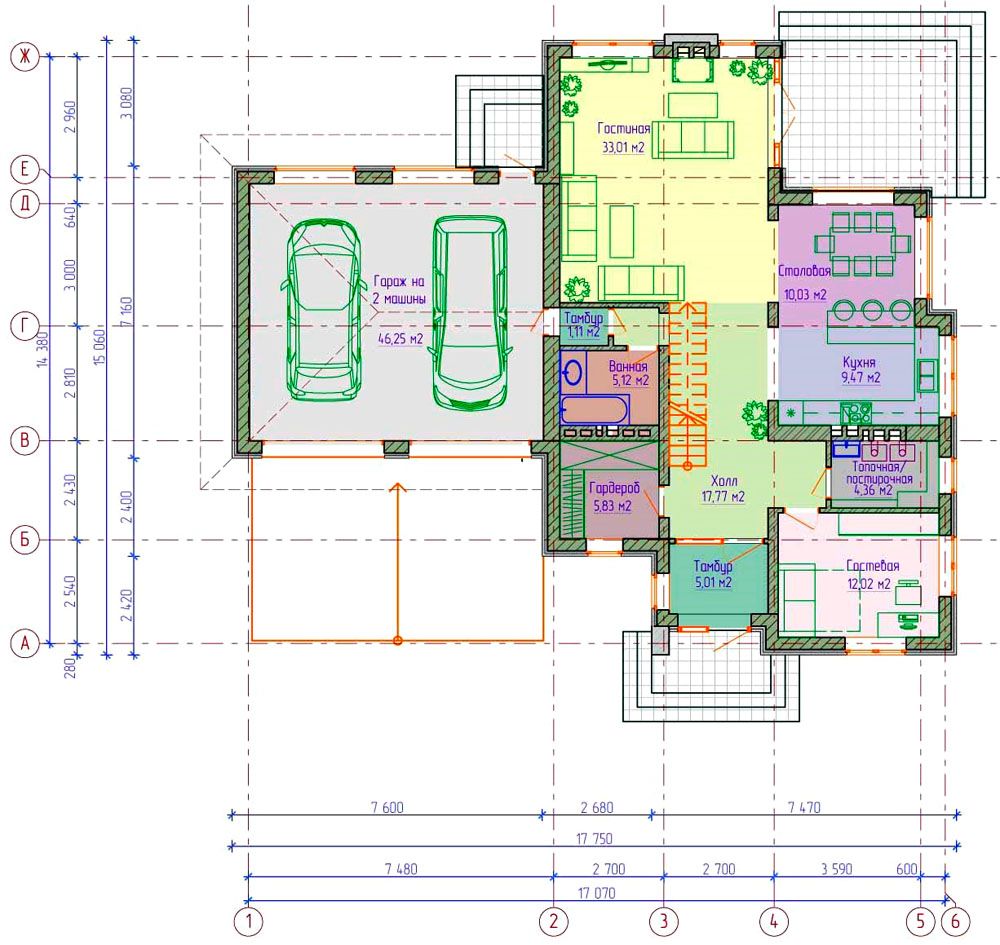

Projects of two-story houses from foam blocks

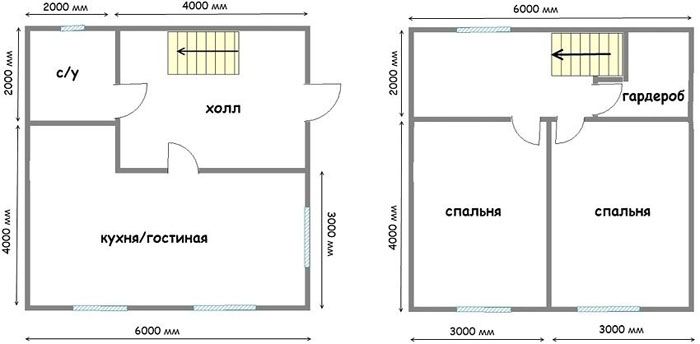

Such structures, with a small building area, allow creating full-fledged living areas on two levels.

The last example demonstrates how to improve the consumer parameters of an economical 6 × 6 foam block house project without excessive costs. To implement such ideas, you need a free space on the land.

Related article:

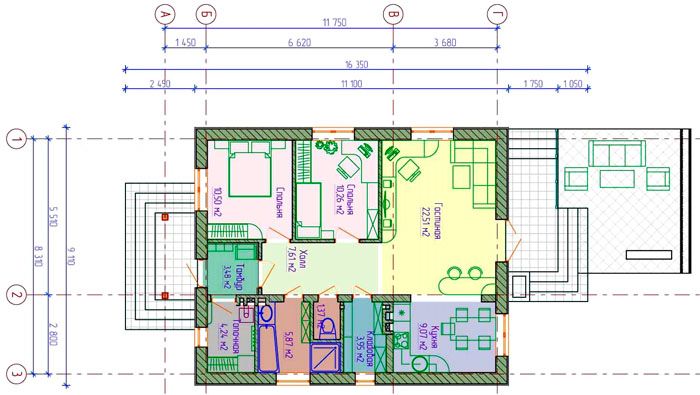

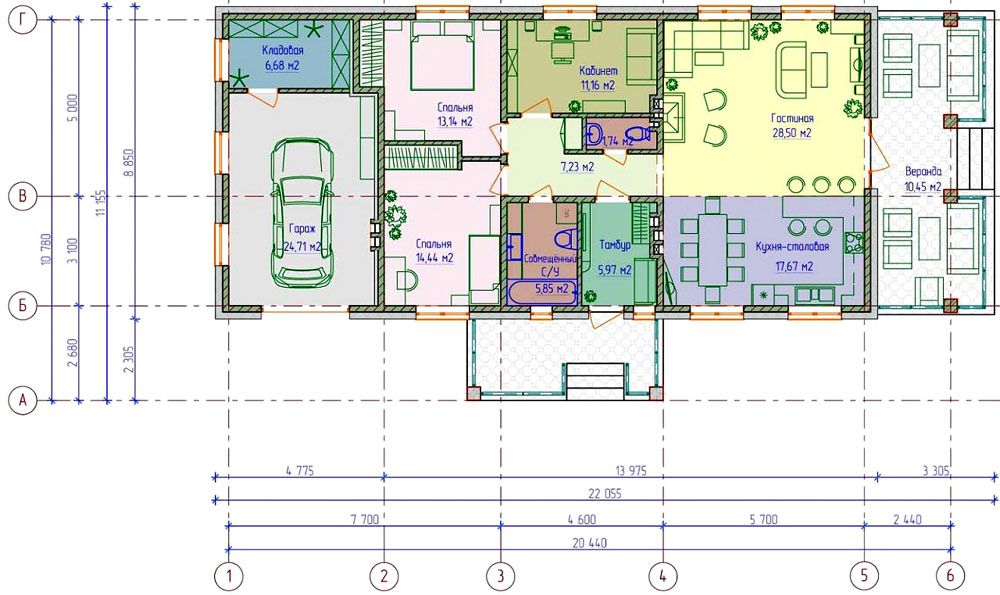

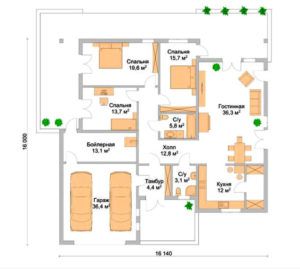

Projects of one-story houses from foam blocks

These buildings provide a comfortable living environment without the tedious climb of stairs.The only significant drawback is the increased requirements for the size of the land plot.

Visualization in 3D format is more informative than an ordinary photo of a one-story house made of foam blocks

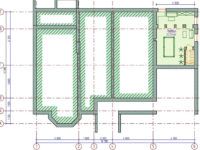

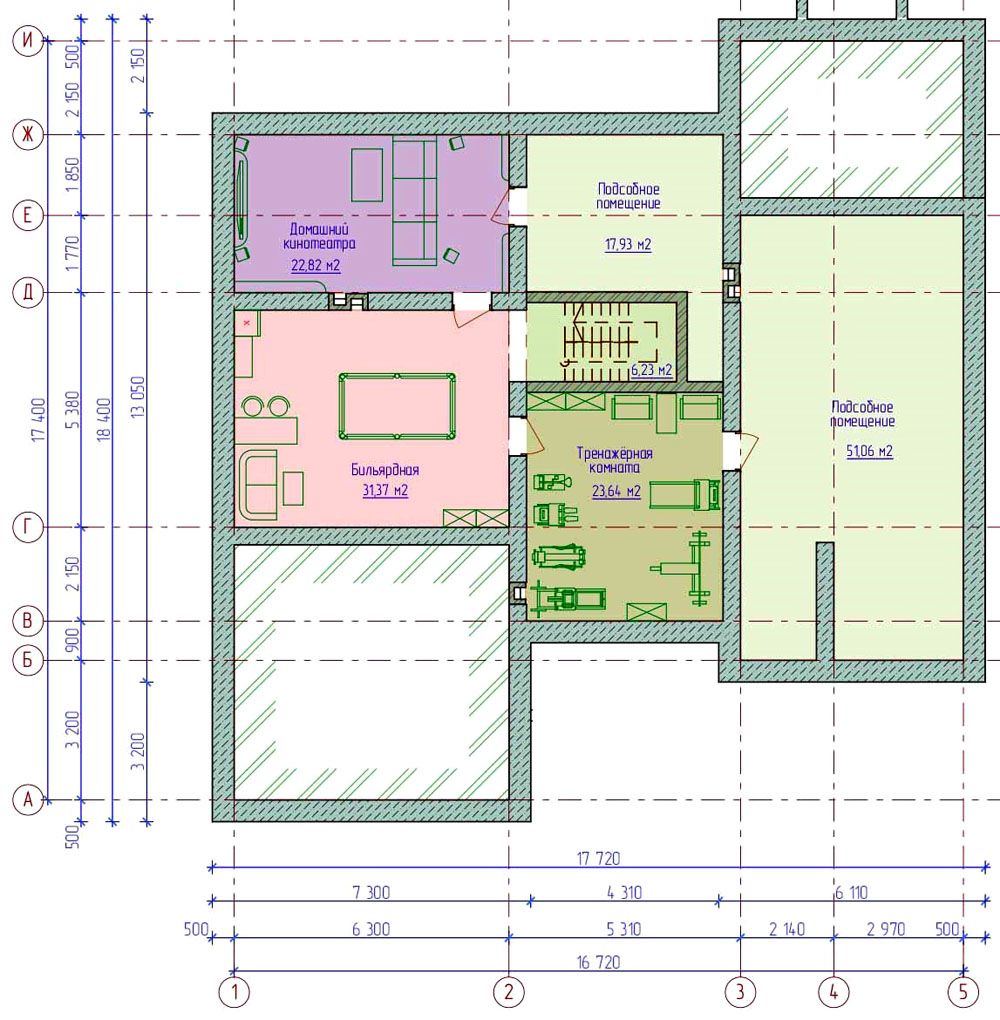

- Basement plan

- Dining room with bay window

- The project of a one-story house 8 × 8 from foam blocks

- The roof area is increasing. Cost increases will be noticeable if expensive ceramic tiles are used.

- Good insulating parameters of modern window units make it easy to implement such ideas.

- In the basement / basement, you can create a complete relaxation area

- When placing the pool, special attention is paid to high-quality waterproofing

- The steam room in the basement is well protected from unnecessary heat loss

- A special ceiling finish will prevent claustrophobic attacks.

Related article:

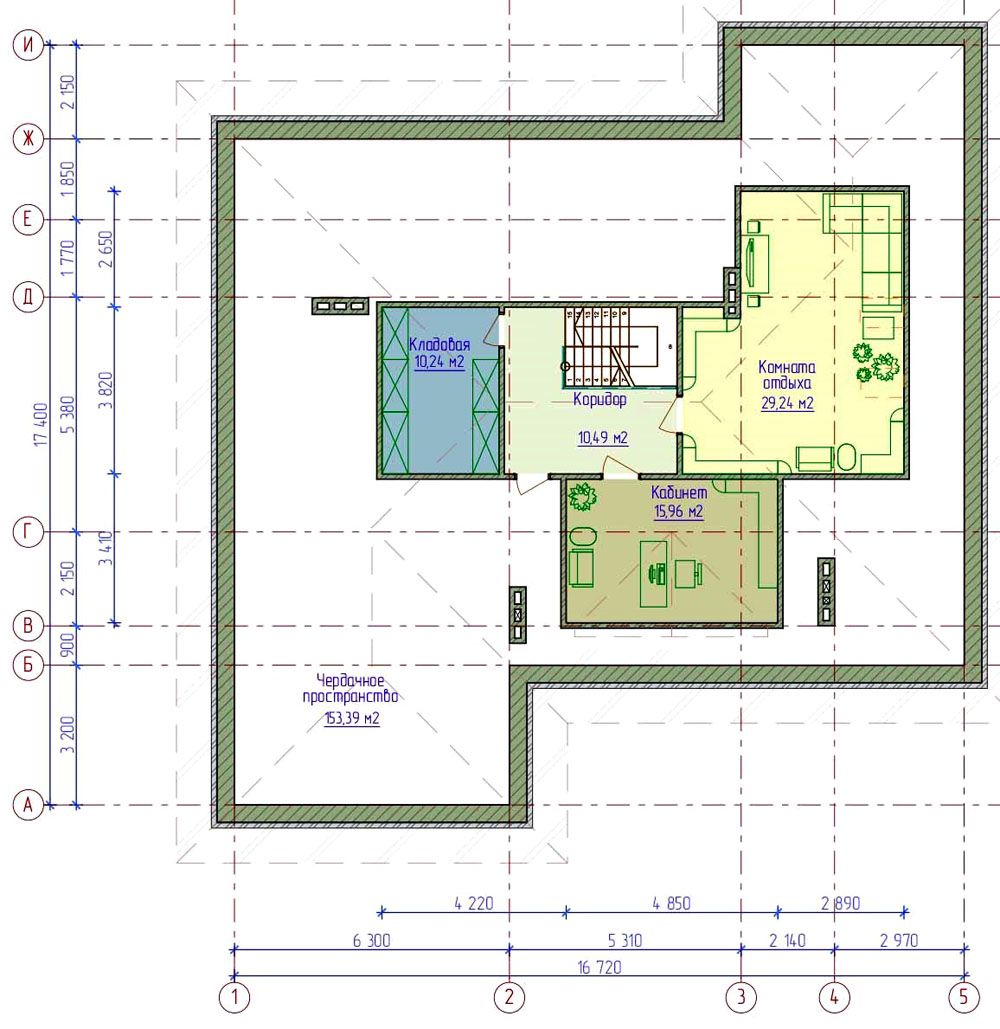

Projects of houses from foam blocks with an attic

With good insulation the space under the roof is converted into full-fledged living quarters.

Related article:

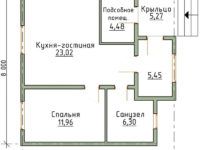

Projects of country houses from foam blocks

This group includes compact structures. A small building spot is implied.

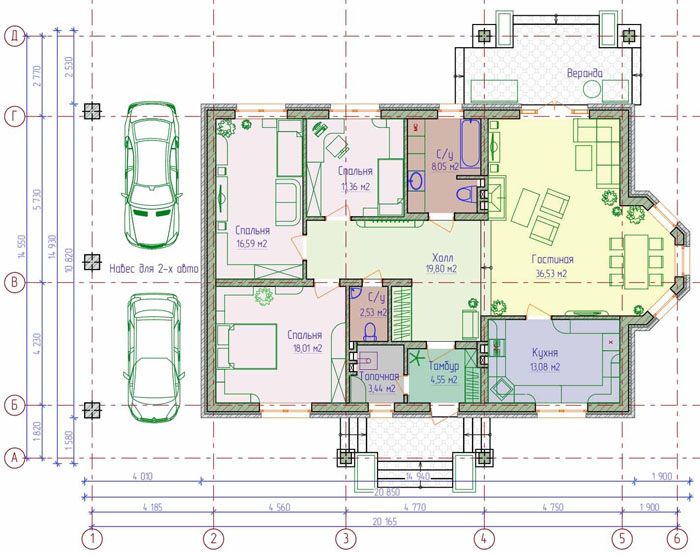

Projects of houses from foam blocks with a garage

In such rooms, they install efficient ventilation, maintain an optimal temperature regime for storing automotive equipment.

Technology for the construction of a private house from foam blocks

It is impossible to determine the final price of the project for a foam block house from a photo. It is necessary to take into account the costs of performing work operations.

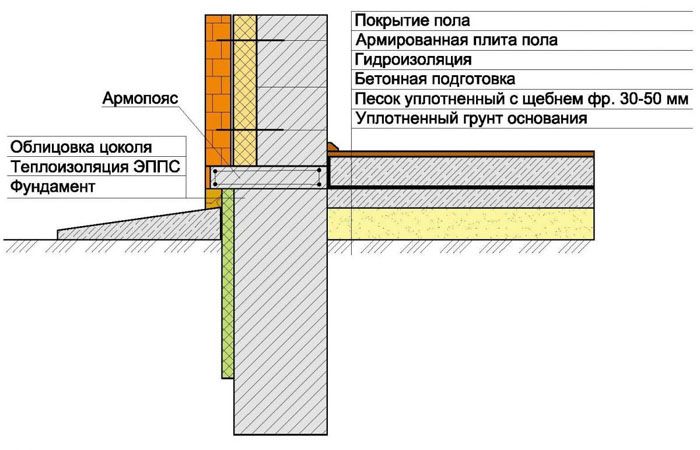

Features of laying the foundation, masonry and wall reinforcement

The type of foundation is chosen taking into account the weight of the building, geology, seismic conditions, snow loads. In the process of laying, be sure to use reinforcement every 4-6 rows. Special reinforcement is made under floor slabs, above window and door blocks.

Roof installation, insulation and facade cladding

The rafter structure is assembled on the ground with subsequent lifting or mounted directly with support on the floor slabs. Be sure to install layers of heat, sound and waterproofing. Particularly careful calculations are made when choosing heavy ceramic tiles.

Typical finishing is carried out using plasters, finishing painting. Outside, you can install a wall of facing brick with an air gap. Various combinations are also used with external insulation, vinyl siding.

How much does it cost to build houses from foam blocks - an overview of prices, taking into account the specifics of the project

It should be remembered that the given prices of projects for the construction of houses from "turnkey" foam blocks imply the basic configuration. The total costs are determined after clarifying the customer's requirements. Use the comments for more information. Submit here your own reviews of projects, construction technologies, materials.

Video of the process of laying foam concrete blocks