Construction of houses from SIP panels - projects and step-by-step instructions when doing work with your own hands

In recent years, a number of new technologies have appeared in the field of individual housing construction, which make it possible to reduce the time required for construction and installation work and reduce their estimated cost. One of these types is the construction of houses from SIP panels, the advantages and disadvantages of which, as well as how to do the work with your own hands, will be discussed in this article in the online magazine homemaster.techinfus.com/en/.

A house made of SIP panels is a lightweight structure that does not require the construction of a complex and powerful foundation

The content of the article [Hide]

- 1 SIP panels for building a house - what is it

- 2 Houses from SIP panels - advantages and disadvantages

- 3 SIP panel classification

- 4 Projects of houses from SIP panels

- 5 What is the difference between houses made of SIP panels for the southern and northern regions

- 6 DIY home construction from SIP panels

- 7 Is it possible to do it yourself SIP panels at home

- 8 Review of prices for building a house from SIP panels "turnkey"

- 9 Reviews of home owners from SIP panels

SIP panels for building a house - what is it

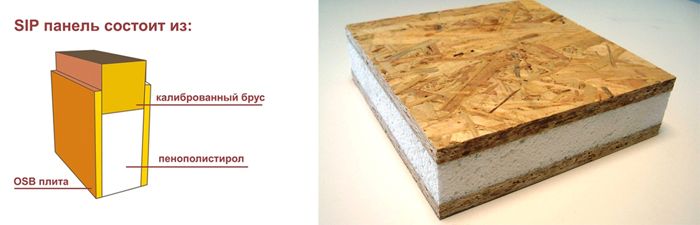

SIP (SIP) -panel is a ready-to-use building structure, which is a product consisting of two layers of sheet materials, between which insulation is laid.

The following are used as sheet materials for framing SIP panels:

SIP panels can only be used as enclosing structures, in this case, the load-bearing elements of the building will be a frame made of timber or other sawn timber, as well as light metal structures (MTK, LTSK). Materials such as mineral wool and polyurethane, polystyrene and expanded polystyrene are used as insulation in the manufacture of such products.

Houses from SIP panels - advantages and disadvantages

Construction technology using SIP panels in our country is called "Canadian", because this country is considered the ancestor of this type of housing construction.

Manufacturing of all structural elements of a house at the factory allows to reduce the time required to complete work on a construction site, which resembles the assembly of a Lego constructor according to a compiled scheme

The advantages of using SIP panels in individual housing construction should be considered indicators such as:

- The light weight of the structures allows you to reduce the costs and time for the construction of the foundation.

- High performance in heat and sound insulation.

- The tight deadlines for the installation work, due to the use of finished products manufactured in the factory in accordance with the project documentation.

- The ability to perform work at any time of the year and in any weather conditions.

- Resistance to biological influences (mold, fungus, etc.).

- Ease of installation with a limited number of construction equipment.

For the installation of heavy structures and elements used for roofing, it is necessary to use a truck crane or other lifting equipment

The following indicators can be considered the disadvantages of SIP panels:

- Flammability and environmental friendliness - depend on the type of materials used in the manufacture of products.

- Possibility of rodent damage.

- The need for careful implementation of insulation and sealing at the junction of individual panels in order to exclude weathering and freezing of structural elements.

Related article:

SIP panel classification

In connection with the emergence of new technologies and, accordingly, new materials, manufacturers began to produce SIP panels that differ in the type of use, which affected their design. For various applications (industrial or civil construction) and types of building structures (wall, floor, partition etc.) various product modifications are available. This applies to the type of insulation used and the material used to frame the products.

The dimensions of SIP panels and their configuration are determined at the stage of development of project documentation, and the basic ones are as follows:

Projects of houses from SIP panels

As for other types of frame housing construction, construction technology using SIP panels involves the manufacture of residential buildings with a height of no more than two floors. Currently, many projects have been developed for various one- and two-story houses for individual construction using this technology. In this section of the article, we present some of them.

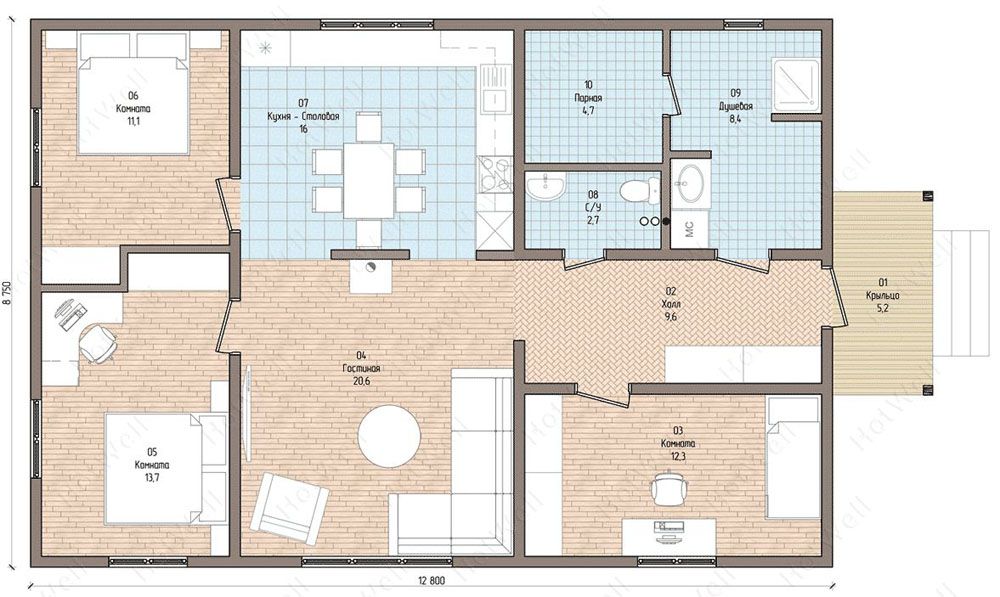

One-story houses

Due to the relatively low cost of construction and the speed of installation work, SIP technology is gaining an increasing number of potential users.

Almost all regions of our country are engaged in the development of design documentation for individual housing construction of SIP-buildings, so there is always the opportunity to find a project tied to a specific region and location, or to link standard solutions.

A practical one-storey house with a pitched roof and a corner window in the kitchen - project "Z24" with a total area of 110.6 m2

The area of a one-story house can be completely different; it is regulated only by the size of the land plot allocated for construction.

Related article:

Two-storey houses

In the category of two-storey houses, there are also quite a lot of typical and individual solutions.

A variety of choices allows you to choose a project of the desired area and layout.

The exterior decoration of a house made of SIP panels can be different, from lining to siding and other finishing materials.

Houses made of SIP panels with an attic

For lovers houses with attic this design is also in the arsenal of designers.

Due to their low weight, houses made of SIP panels can be placed on a foundation made on screw piles

The layout of the house, which has an attic, is the most popular among domestic developers.

The area and layout of a house with an attic can be completely different and can satisfy the requirements of any developer

What is the difference between houses made of SIP panels for the southern and northern regions

A distinctive feature of houses made from SIP panels for the southern and northern regions of our country is their thickness, which determines the thermal characteristics of both an individual product and the construction object under construction as a whole. As it was already written above, the thickness of SIP panels varies from 110 to 270 mm, but depending on the location of the object under construction, it can be changed in one direction or another.

When building houses using this technology, especially in the northern regions of our country, special attention is paid to the places where the individual panels are connected to each other in order to ensure the impossibility of heat leakage through these places of building structures.

DIY home construction from SIP panels

In order to reduce the cost of building a house, the design of which involves the use of SIP panels, installation work can be done by hand.

If there is a sufficient number of workers, the installation of SIP panels can be performed without the use of construction equipment

In this case, in order to avoid mistakes and problems during further operation, it is necessary:

The foundation for frame houses can be made using screw piles, strip type or in the form of a monolithic slab, as a "floating foundation"

Having decided on type of foundation and having made it, you can carry out the assembly at home, having received a house kit from the manufacturer with accompanying documentation.

All work on assembling a house from SIP panels can be described as follows:

Related article:

Is it possible to do it yourself SIP panels at home

If you have free time and desire, SIP panels can be made by hand, however, it should be noted right away that such products will have slightly different characteristics than those made in the factory.

For making at home, in addition to OSB sheets and insulation, you will need glue that ensures their connection (Macroplast UR 7229 (7228), Kleyberite, AveniR, TOP-UR (15-40)), as well as a press or a vacuum pump. In addition, for do-it-yourself manufacturing, you will need a mounting table and a thermal cutter, designed for cutting panels (insulation) in accordance with the specified dimensions.

Review of prices for building a house from SIP panels "turnkey"

The cost of building a house from SIP panels depends on indicators such as:

At present, the cost of construction of such turnkey facilities, excluding finishing and utilities, as of the III quarter of 2018, is presented in the following table.

| Region of RF | Cost (as of August 2018), rubles / m2 total area |

|---|---|

| Moscow and Moscow region | 9300 |

| Yekaterinburg and Sverdlovsk region | 9500 |

| Yaroslavl and Yaroslavl region | 10000 |

| Krasnodar and Krasnodar Territory | 10000 |

| Arkhangelsk and Arkhangelsk region | 8000 |

Housecompletes from SIP panels are produced in all regions of our country, which is due to their demand among developers

Reviews of home owners from SIP panels

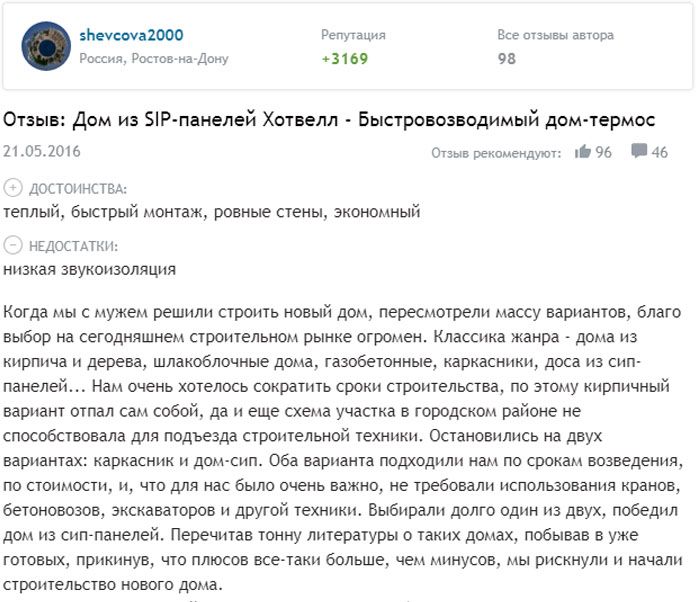

Thanks to the presence of the Internet, a modern person always has the opportunity to find a review about a particular product or article. This fully applies to building structures, as well as technologies - in our case, to houses built using SIP panels. Here are some reviews of real users who have tested this construction technology on themselves:

Reviews of real owners of houses from SIP panels: video